We have an established background in meeting the needs of companies operating in the Aerospace and Defence sectors. The chemical etching process is ideal for producing components that are used in critical applications. We have a skilled material handling department and all materials are fully traceable and are quality checked to ensure correct grades and specifications are met. Chemical etching produces intricate parts that have no stress, burrs, or distortion. The process delivers an incredibly consistent output that is ideal for the rigours of the aerospace and defence sectors.

Chemical etching offers consistent results, and the metal etching process can meet extremely tight tolerances that enable parts to perform under extreme conditions. We have five multi-chamber etching machines, capable of fast, accurate etching on a range of metals. This is all supported by our production team, who are highly experienced in the demands and expectations required in these critical industries. See our materials list.

For more information on how we can reduce your costs & improve lead time contact our dedicated account managers on 01480 226699 or email enquiries@photofab.co.uk.

Download our brochure to see what we bring to the aerospace and defence sector:

Trusted to deliver

Parts for the aerospace and defence sectors have key needs such as full traceability of the raw materials, fully documented and followed process control, fast and reliable deliveries, and high levels of quality.

Chemical etching is also a cost-effective process that’s ideal for parts with complex geometry thanks to minimal amount of burrs and distortion compared to other production methods. We produce components for the aerospace and defence sectors in numerous metals, such as steel, stainless steel, aluminium, copper alloys and nickel alloys. You can view the full range of materials on our materials page.

Components for every need

A huge number of parts are suitable for use in the aerospace and defence sectors. We have produced the following for this industry:

- Actuators

- Contacts

- Connectors

- Corporate Products

- Diaphragm

- Elements

- Enclosures

- Encoders

- Heat Exchanger Plates

- Fuel Cell Plates

- Brackets

- Filters

- Flat Springs

- Formed Components

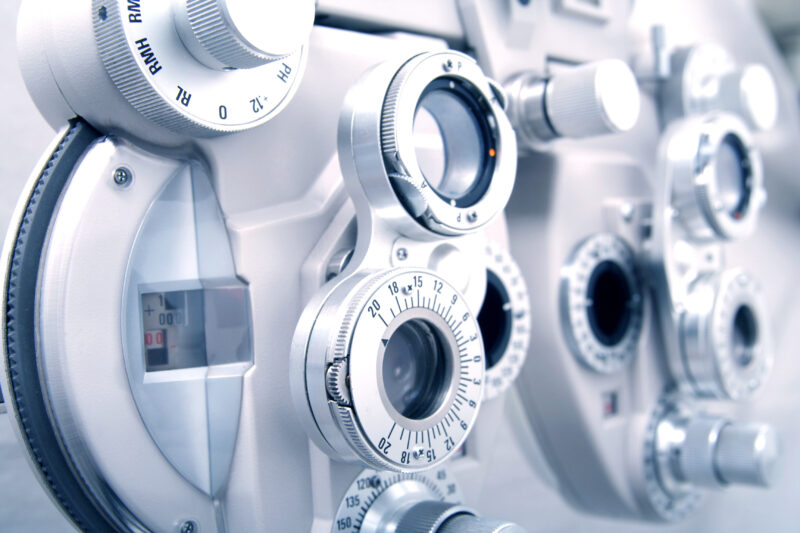

- Instrumentation Dials

- Keypads

- Laminations

- Nameplates

- Intake Grilles

- Busbars

- Apertures

- Screening Cans

- Shims

- Solder Tags

- Spacer washers

- Spring Clips

- Springs

- Tear Bars

- Meshes

- Terminals

Committed to improvement

We appreciate that the sector faces continually changing requirements through research and development, or legislation in terms of innovation, quality, speed, etc. That is why we are always aiming to deliver on the cutting edge and deliver the latest standards. Get in touch with us about your needs in the sector to see what we can do for you.

The benefits of chemical etching for aerospace and defence

- Burr-free & stress-free manufacturing method

- High temperature and corrosion resistance

- Single piece up to high volume

- Fully traceable and managed in-house

- Very high tolerance

- Variable bar heights

- High accuracy and consistency

- Cost effective tooling and manufacture

- Fast turnaround, from 24 hours

- ISO 9001, 14001, 18001 and SC21 accredited

- Dedicated Account Manager

- Over 50 years in the Aerospace and Defence sector

We take great care in the selection of the right metal for the component application. Wherever possible, we use a special photo-etching grade, which is more uniform in thickness and flatter than normal stock. Our engineers and metallurgists will be pleased to advise on the grade of metal suitable for your application.

An extensive range of metals in various degrees of hardness and thickness are held in stock ready to meet a Rapid Delivery service. Metal thickness of 0.005 to 1.5 mm is suitable for through etching, while any thickness of sheet material can be surface etched.

The following list of metals is suitable for chemical etching and forming, and many are held in stock. If you don’t see what you need, please telephone us on 01480 226699 or contact us using the form below.

Stainless Steels

Austenitic (301, 302, 304, 316, S526, S527), Martensitic (321, 410, 420), Precipitation Hardened (17/7), Heat Resisting (309, 310)

Other Steels

Mild Steel, Carbon Steel, Tool Steel, Spring Steel, Transil, Losil.

Nickel Alloys

Nichrome, Mu Metal, Nickel Copper (70/30), Inconel, Nickel Brazing Foil.

Nickel/Iron Alloys

Invar, Alloy 42, Kovar, Radio Metal.

Copper

Tough Pitch 101, Oxygen free – High Conductivity.

Copper Alloys

Brass, Phosphor Bronze, Beryllium Copper, Nickel Silver, Ferry Constantan.

Aluminium and Aluminium Alloys

Silver and Alloys

Silver, Silver Alloys, Silver/Copper, Silver/Palladium, Silver Brazing Alloys.

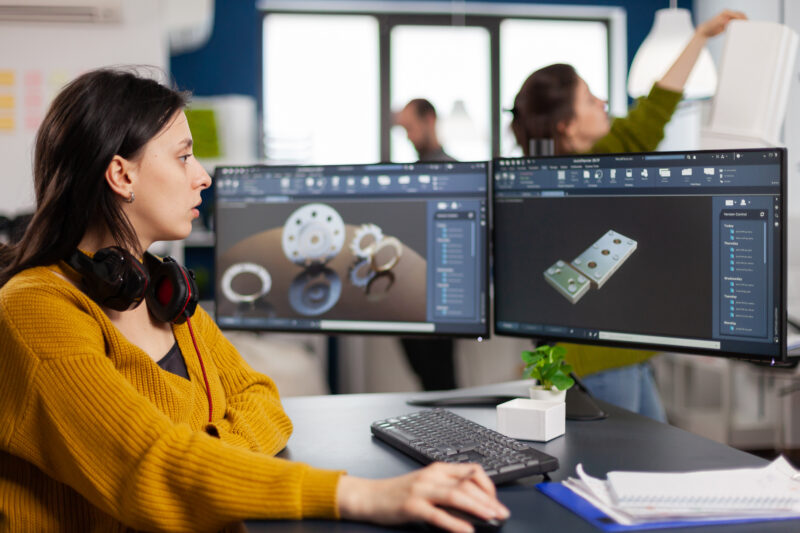

DEDICATED engineering

We understand the importance of skilled engineering when designing components and putting them into production. Therefore, we have heavily invested in a dedicated secondary engineering unit, the aim of this is to offer an even greater service and flexibility to our customers.

Originally set up to provide an in-house solution to support the etching division, it has proven so popular with our customers that we are now offering toolroom, forming and finishing as stand-alone services. This means our customers now have access to a new level of flexibility – enjoying the convenience of full-service manufacture or pick and choose services to suit them. It truly is a complete service we offer.

We continue to offer cutting-edge services and outstanding lead times, and we can do so because of continuous investment in our people and our processes, leading to class-leading output and lead times – including our rapid 24 hour turnaround service.

The benefits of

working with us

We are world leaders in the development of photochemical technology to produce intricately shaped components. We have produced over 80,000 different components over the years and are highly regarded for our chemical etching process. Our engineers offer many services, and will offer advice to improve the product and reduce the costs.

24-hour quotation service

Dedicated account managers

Rapid manufacturing service

Cost saving stock of uni-tooling

Etched fold lines for tool-free forming

Full manufacturing service and supply chain management

Access to manufacturing and technical advice and expertise

Quality accredited to ISO 9001, ISO 14001, ISO 45001 and SC21 Bronze

The Photofab difference

One of the key reasons we enjoy high levels of customer retention and longevity is the team of dedicated account managers. This ‘single point of contact’ throughout the whole process, ensures a personal service, and pride in the quality and reliability of the entire service.

Customers rely on their dedicated contacts’ understanding and in-depth knowledge of their specific requirements and know the highest standards will always be met using the most efficient and cost-effective methods.

This consistent customer service is the foundation of our customer loyalty and is maintained throughout every department and every stage of production. Put us to the test for your next project and call one of our account managers on 01480 226699 or use our customer enquiry form, we would love to hear from you.

start your production journey today

If you are looking to find a complete service include dedicated engineering to design and implement your solution, get in touch with us. You’ll be allocated your own dedicated account manager who is always on hand to advise and take care of everything for you. Call us on 01480 226699 or contact us now to see how we can add an extra dimension to your manufacturing project. Keep up to date by following us on LinkedIn.

TAKE A LOOK AT OTHER

SECTORS we Supply

To find out how we can help you

Get in touch today