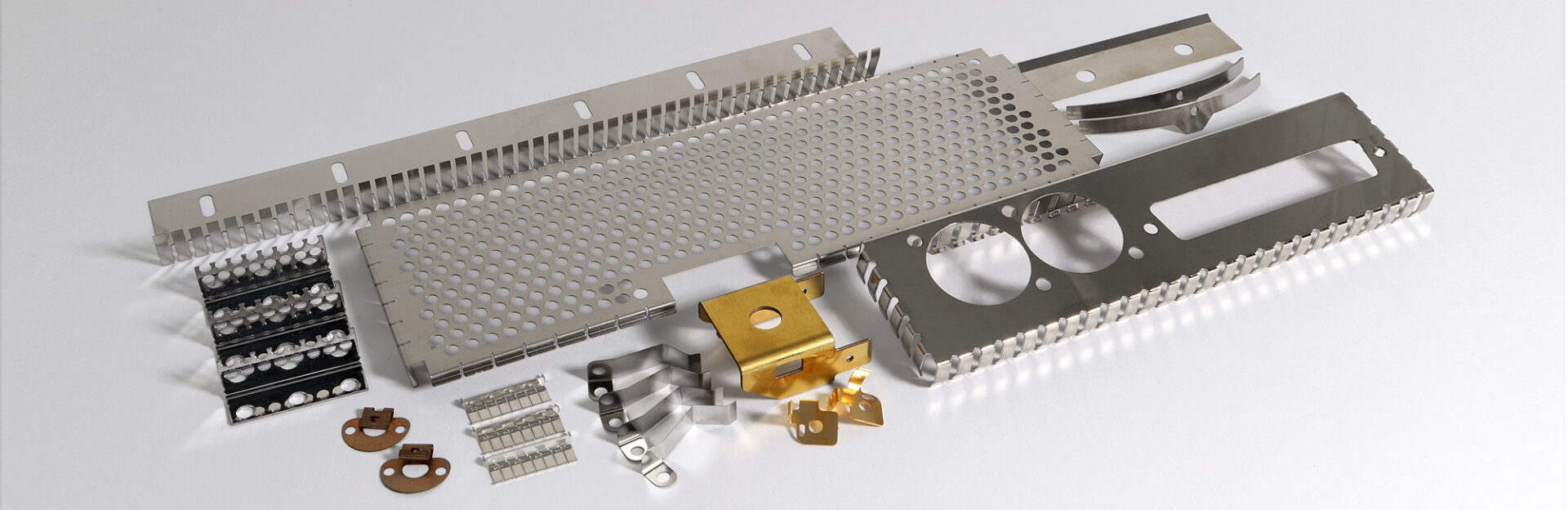

Photofab has a wide experience in delivering sheet metal forming on finished components for our customers. For over 50 years, Photofab has been producing bespoke metal components. Metal or press forming is the process of fashioning parts into their desired final shape. Photofab prides itself on offering a complete service, which is why we offer forming on components, meaning that Photofab can be your all-in-one supplier of metal parts. In addition to manufacturing your parts we are able to offer a variety of forming solutions to suit your individual needs. Whilst we typically work in with prototyping and low volume production, we do have the expertise and equipment to offer competitive rates for higher volume forming production.

We find that for parts formed using hard tooling a tolerance of +/- 0.1mm is generally required, although this is dependent of the complexity of the forming and the thickness of the part. We do advise our customers that if your tolerances do not need to be as strict, it can be a more cost-effective solution to relax them – if your application allows it.

For more information on how we can reduce your costs & improve lead time contact our dedicated account managers on 01480 226699 or email enquiries@photofab.co.uk.

Photofab offer the following sheet metal forming techniques:

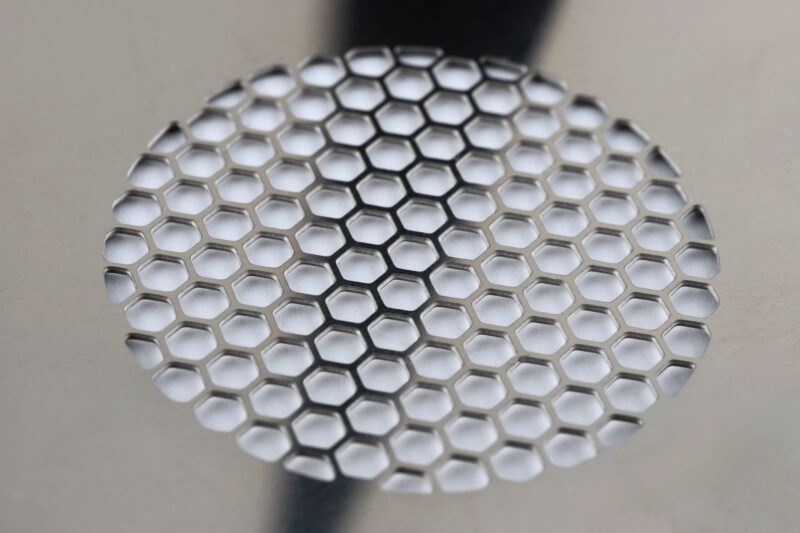

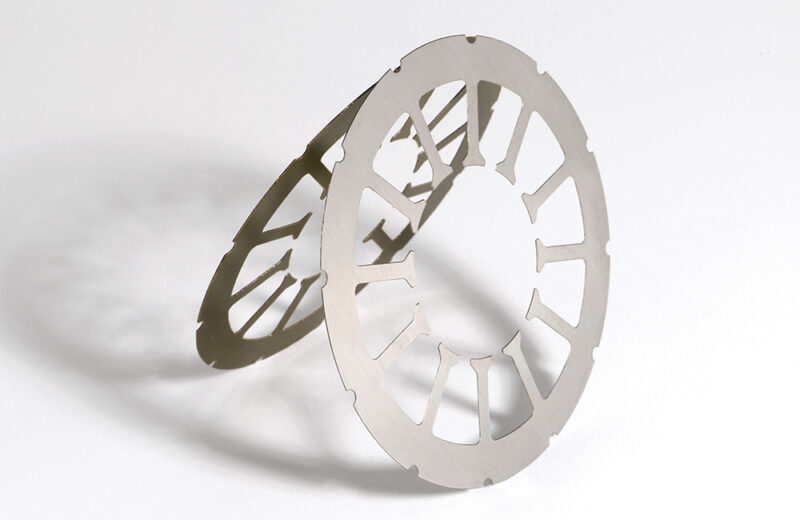

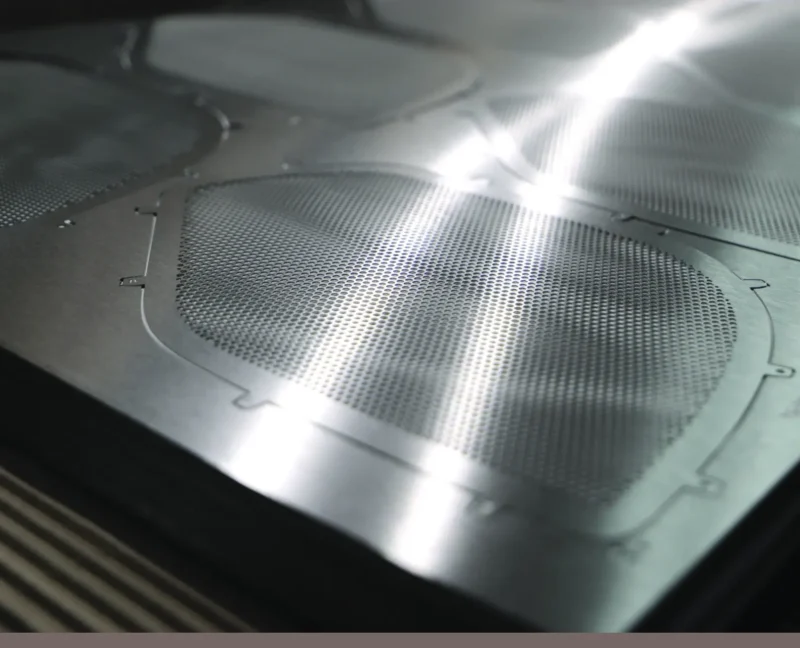

Half Etch Metal Forming

We are able to etch lines into a part. These lines are only etched halfway through the metal. By doing this, the metal can be bent. This method has no form tooling charge and is ideal for simple angle bends. The parts can be formed inhouse by us, or on site by yourselves, depending on your preference. It is the least accurate method and requires more generous tolerances, which is why we only recommend it for simple designs.

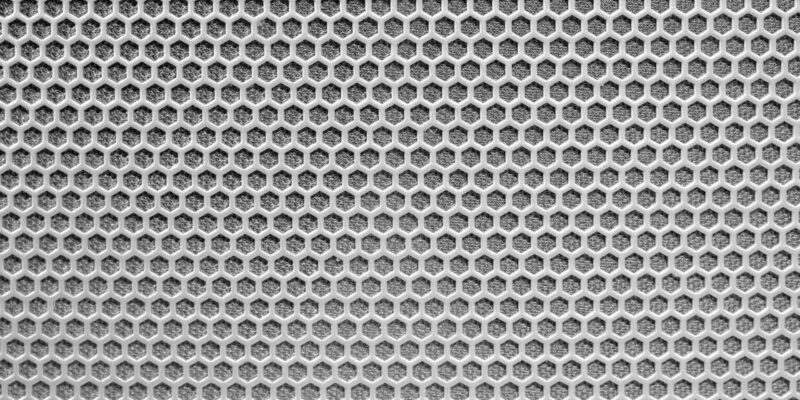

Uni-tool Metal Forming

Photofab have developed a custom uni-tool which is an adaptable piece of hard tooling. We can use this custom tool to achieve the forming you require. The tool delivers good accuracy. This method also has no tooling charge, and a low part price with fast turnaround. This is another method that is ideal for simple designs, and we tend to use it for prototyping and low volume production up to approximately 200 pieces.

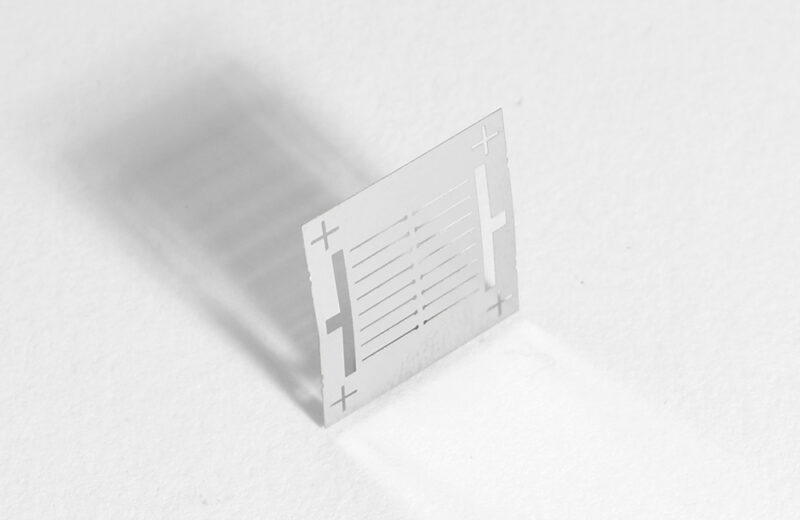

Knife and Fork Prototyping

This is a hard tooling method, which uses several more complicated pieces of universal tooling and can cope better with more complicated parts. Even so, there is no form tooling charge. This is our recommended method for intricate forming. This is typically used for prototypes and low volume production up to 200 pieces.

Hard Form Tooling

The hard tooling method involves us creating custom hard tooling to fit into toggle presses. This custom tooling can only be used one one type of part, and a custom tool for each type of component is required. We charge from £50 upwards depending on complexity for the tooling. This method is ideal for intricate, high volume production. It also delivers very good accuracy at tight tolerances, generally within 0.1mm.

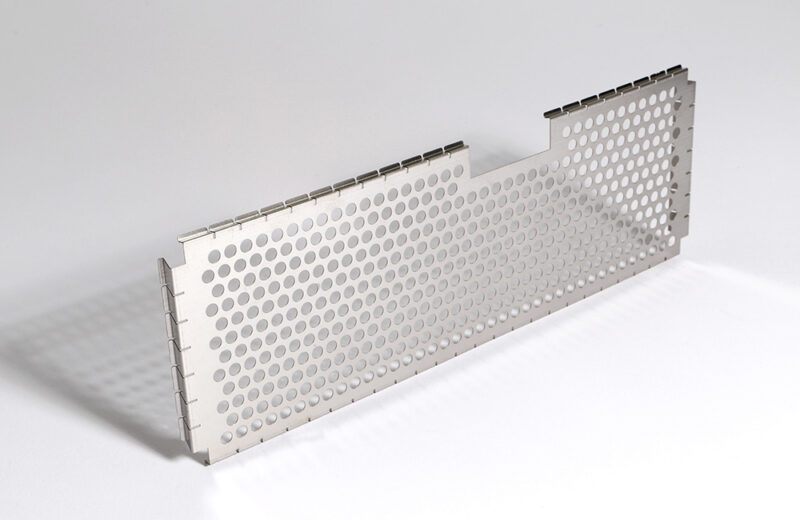

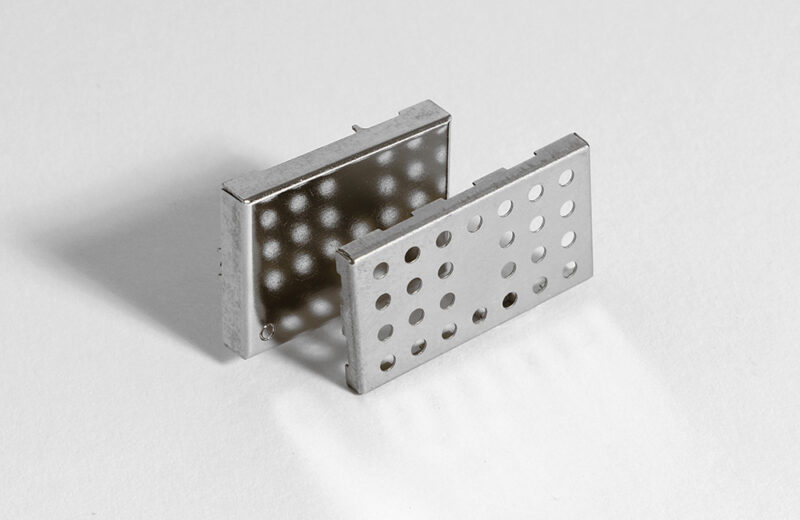

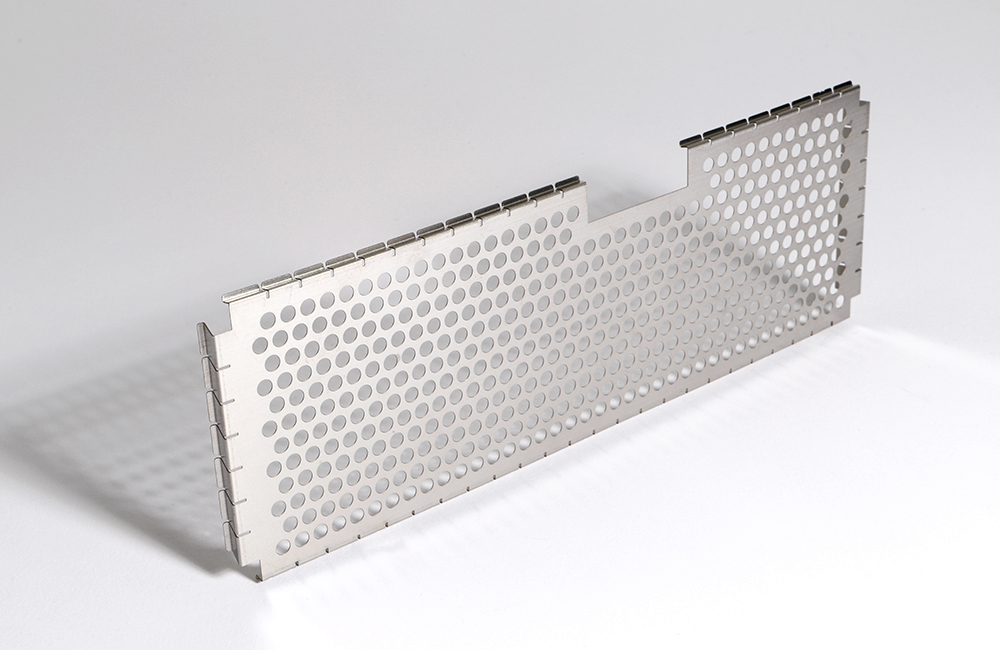

Screening Can Forming with no Tooling Costs

Our Screening Can tooling method has the benefit of no tooling cost. It uses a series of tools developed at Photofab which are adaptable and specially engineered to produce Screening Cans. This method provides a low-cost option for Fingered lids. It is suitable for parts up to 200mm in length and width. The legs need to be a minimum length of 3mm, and must be rectangular for this particular method.

Soldering and Spot Welding Service

We also have the equipment and expertise to solder and spot weld parts together for you. Photofab whether your component require a seam soldered or two pieces spot welded together, we can deliver an outstanding final result.

General Toolroom Services

Along with our other range of services, Photofab regularly provide precision surface grinding of metal, along with milling, turning, reaming, drilling and much more. If you have a need for a discipline not mentioned, please do not hesitate to get in contact with us. Our team of expert engineers will work closely with you to come up with a solution that meets your desired outcomes.

Component Assembly

We facilities offer us the capability to assemble a diverse range of components, which allows our customers to reduce their supply base by using Photofab’s logistical control team. We have a highly skilled team who will take your requirements, manufacture the components from raw materials, then assemble to your specifications. Photofab is proud to offer a complete service.

The benefits of metal forming components with Photofab

- Various Forming Options

- High accuracy pieces

- Customised parts – you design it – we make it!

- Prototyping to volume production

- Competitive rates for high volume

- Cost-efficient methods

- Range of tooling, including custom

- Fast prototyping to meet your needs

- High volume capabilities

- Dedicated Account Manager

These facts along with short delivery times – in five days or less, are the reasons so many companies turn to Photofab as their preferred supplier. Get in touch with us today to join the growing number of manufacturers who rely on Photofab’s expertise to supply them with bespoke components.

DEDICATED engineering

Photofab understands the importance of skilled engineering when designing components and putting them into production. Therefore, we have heavily invested in a dedicated secondary engineering unit, the aim of this is to offer an even greater service and flexibility to our customers.

Originally set up to provide an in-house solution to support the etching division, it has proven so popular with our customers that Photofab are now offering toolroom, forming and finishing as stand-alone services. This means our customers now have access to a new level of flexibility – enjoying the convenience of full-service manufacture or pick and choose services to suit them. It truly is a complete service from Photofab.

Photofab continues to offer cutting-edge services and outstanding lead times, and we can do so because of continuous investment in our people and our processes, leading to class-leading output and lead times – including our rapid 24 hour turnaround service.

The benefits of

working with us

We are world leaders in the development of photochemical technology to produce intricately shaped components. We have produced over 80,000 different components over the years and are highly regarded for our chemical etching process. Our engineers offer many services, and will offer advice to improve the product and reduce the costs.

24-hour quotation service

Dedicated account managers

Rapid manufacturing service

Cost saving stock of uni-tooling

Etched fold lines for tool-free forming

Full manufacturing service and supply chain management

Access to manufacturing and technical advice and expertise

Quality accredited to ISO 9001, ISO 14001, ISO 45001 and SC21 Bronze

The Photofab difference

One of the key reasons Photofab enjoy its customer retention and longevity is the team of dedicated account managers. This ‘single point of contact’ throughout the whole process, ensures a personal service, and pride in the quality and reliability of the entire Photofab service.

Customers rely on their dedicated contacts’ understanding and in-depth knowledge of their specific requirements and know the highest standards will always be met using the most efficient and cost-effective methods.

This consistent customer service is the foundation of our customer loyalty and is maintained throughout every department and every stage of production. Put us to the test for your next project and call one of our account managers on 01480 226699 or use our customer enquiry form, we would love to hear from you.

start your production journey today

If you are looking to find a complete service include dedicated engineering to design and implement your solution, get in touch with us. You’ll be allocated your own dedicated account manager who is always on hand to advise and take care of everything for you. Call Photofab on 01480 226699 or contact us now to see how Photofab can add an extra dimension to your manufacturing project. Keep up to date by following us on LinkedIn and Twitter.

TAKE A LOOK AT OTHER

PRODUCTS FROM PHOTOFAB

To find out how we can help you

Get in touch today