Prototyping to Production – Streamlining the Metal Design Process

Moving from concept to production is one of the most crucial stages in metal product design. It’s the point where creative ideas morph into manufacturing practicality. This transition can often become bogged down by delays, miscommunication and unforeseen costs. For those of us in the business of precision metal fabrication, streamlining this process is essential, ensuring both efficiency and quality in the final product.

We’ve supported countless product designers and engineers through this critical phase. Over the years, we’ve developed insights into removing common challenges, harnessing the power of rapid prototyping and fostering effective collaboration.

Drawing on our experience, here’s how we see the path to an optimised design-to-production workflow.

Addressing Key Challenges in Metal Component Design

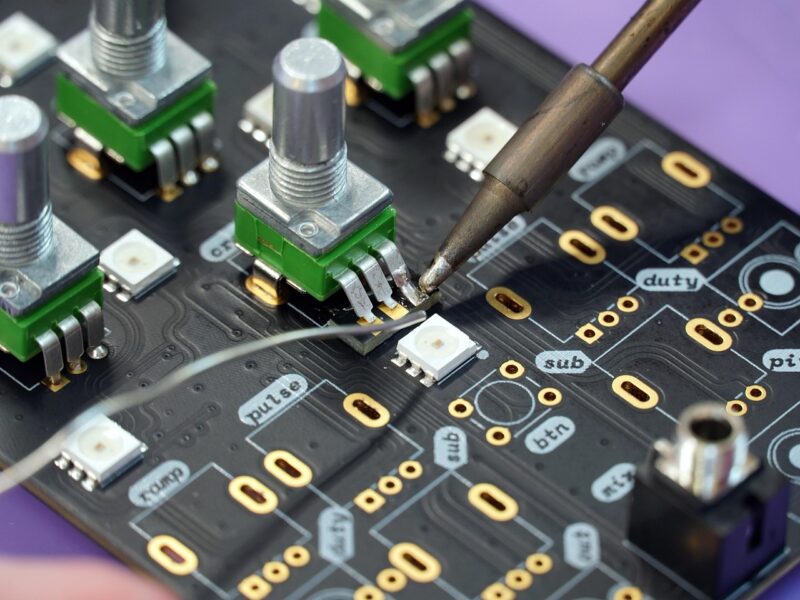

One of the most persistent hurdles in transitioning from concept to production is the way materials behave during manufacturing. While component design companies rely on precise calculations, real-world demands can alter performance slightly. Tolerance variation and traditional fabrication limitations methods can significantly influence a product’s quality. Material complexities add layers of unpredictability and emphasise the need for thorough validation during both the design and prototyping phases.

That’s why it’s imperative to use the technical nous of an expert metal production company.

Another challenge lies in overcoming the roadblocks in the prototyping process. Traditionally, developing prototypes has involved a labour-intensive cycle of manual adjustments and testing which can significantly extend timelines. A prototype rarely is perfect the first time. For metal design agencies, each variation demands careful revision, testing and refinement, often causing delays that disrupt project flow and push deadlines further than anticipated. This issue is amplified when design needs align with intense market demands, where extended iteration cycles can hinder the ability to meet these expectations competitively. The inefficiency not only costs valuable time but can also inflate the overall expenditure allocated to the project’s development stage.

Rapid Prototyping as an Essential Tool

At the heart of a streamlined transition from design to production is rapid prototyping. This process allows us to quickly produce physical representations of a design, testing for functionality, manufacturability, and aesthetic qualities.

Here’s why it’s indispensable for our industry:

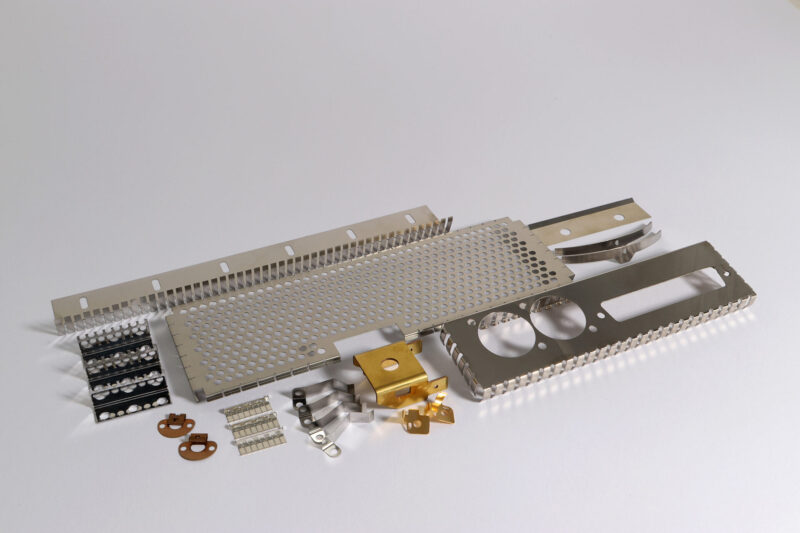

- Early Validation of Designs

Rapid prototyping allows us to test designs in realistic conditions, identifying potential flaws before production begins. For example, when working with complex metal components in electronics applications we can evaluate tolerances and stress performance early in the design process. - Cost Savings Over Time

While prototyping involves an upfront cost, it prevents large-scale production errors, ultimately saving money. Identifying a minor flaw in a design during prototyping could prevent thousands of defective parts. - Shortened Feedback Cycles

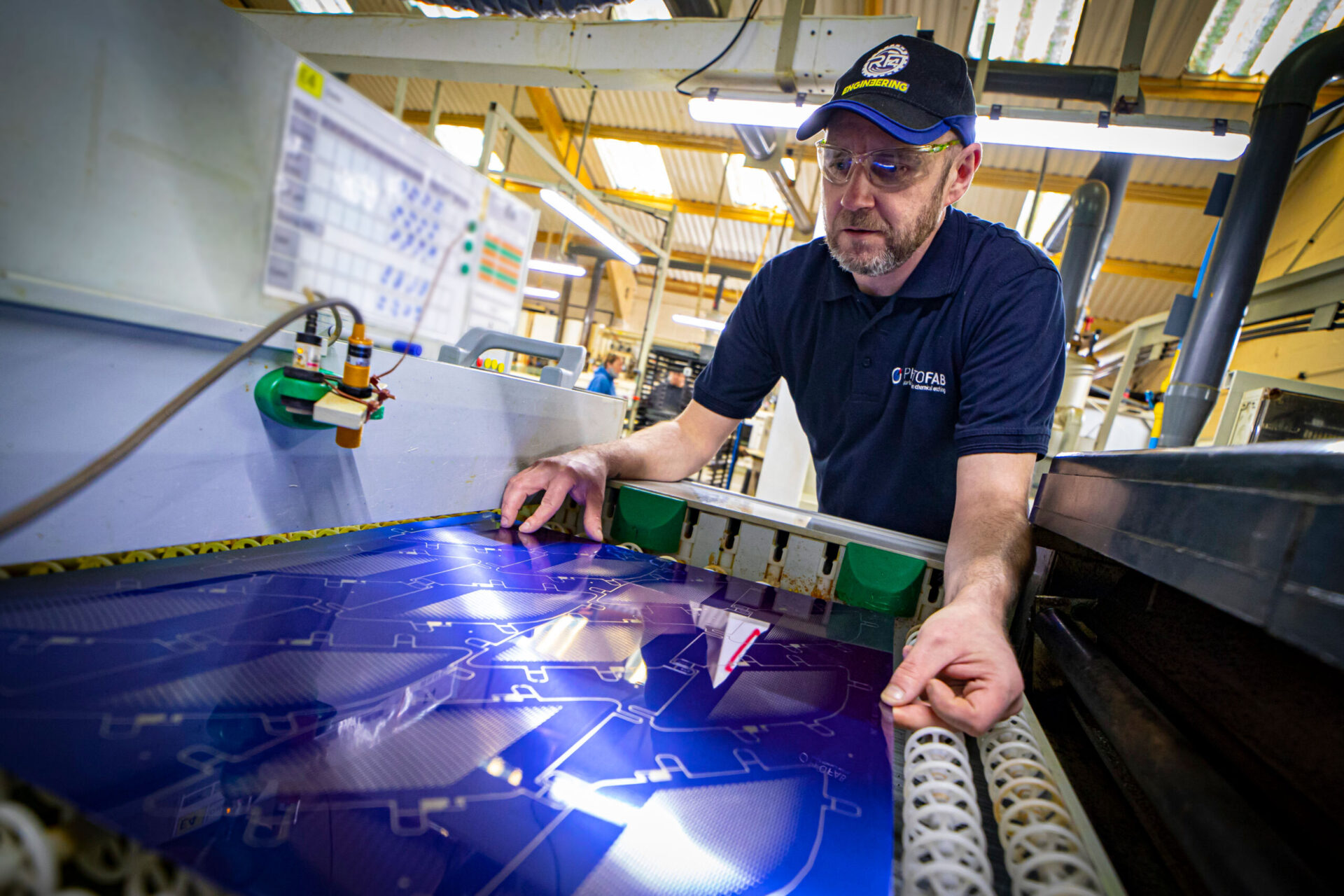

Our modern prototyping techniques, through processes like chemical etching, enable faster turnarounds. This agility allows for quicker iterations, meaning optimisations can be made in days rather than weeks.

Chemical etching allows for incredible precision where intricate metal designs with tolerances down to 25 microns can be tested and refined rapidly. This ensures that by the time the product reaches full-scale production, it’s been comprehensively evaluated for performance and manufacturability.

Collaboration as the Key to Success

We understand that even the most skilled design teams need support to bring their concepts to life. Collaboration with experienced manufacturing specialists is vital. By leveraging the expertise of fabrication partners, designs can be reviewed for efficiency and adjusted to work seamlessly with available production methods.

Early engagement with fabricators is essential to achieving a seamless transition from design to production. By involving experts at the outset, opportunities for optimisation become clear. Collaborating closely with fabricators also provides access to a wealth of manufacturing insights, from material characteristics to tolerance capabilities and best practices, helping to avoid costly missteps that may not be apparent during the design phase.

An agile workflow further enhances efficiency, as feedback between design and production teams ensures adaptability to changing requirements. Equally important is maintaining clear and detailed documentation. Accurate design files, material specifications and tolerance details are vital to preventing misunderstandings and ensuring that production aligns perfectly with the original vision. Together, these steps create a robust framework for innovation and high-quality execution.

One example we’ve encountered involved creating a precision component for a medical device. Early collaboration allowed us to troubleshoot potential issues in the design phase, recommending minor adjustments that avoided significant costs down the line. By the time the product hit production, it achieved unparalleled accuracy and quality.

Building an Optimised Workflow

Streamlining the metal component design process is about more than just saving time or money, it’s about creating a repeatable framework for a successful partnership. When rapid prototyping is paired with collaborative teamwork, every stage of the transition from concept to production becomes smoother and more reliable.

We take pride in guiding our partners through this complex stage, helping them make their ideas a reality. By prioritising innovation, clear communication, and our shared expertise, we’re driving meaningful improvements in the manufacturing industry.

What steps can we take together to enhance your design-to-production process? We’re here to support you in creating solutions that are not only innovative but realistic and scalable too.