Chemical Etching v Water Jetting

Why Chemical Etching Is One Of The Best Water Jetting Alternatives

Engineers and designers are spoiled for choice when it comes to cutting technologies. Two methods that often come up for comparison, especially for thin, complex or burr-free parts, are chemical etching and water jetting.

If you’re deciding between chemical etching or water jetting for your next project, you’re likely looking for a process that offers precision, cost-efficiency and high quality. While water jetting is a powerful and well-established technology, it’s not always the perfect tool for every job due to its tendency to leave burrs and add stress to the material being cut.

Discover the key differences between chemical etching and water jetting, including key water jetting disadvantages, and find out why photochemical etching stands out as one of the most effective water jetting alternatives for a wide range of applications.

What is Water Jetting?

Water jet cutting (or waterjetting) is an abrasive machining process. It uses a high-pressure pump (often up to 60,000 psi or more) to force water through a tiny nozzle, creating an ultra-focused, supersonic stream. For cutting harder materials like metals, an abrasive grit (usually garnet) is mixed into this water stream. This abrasive jet erodes the material along a programmed path, effectively cutting through it. In essence, it’s like a highly accurate, ultra-powerful pressure washer.

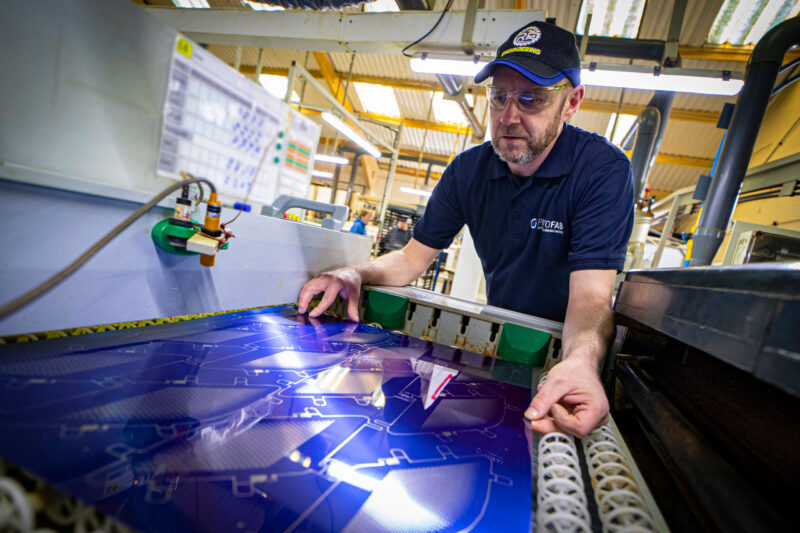

But what is chemical etching? Chemical etching, on the other hand, is a subtractive manufacturing process that involves several steps, from the initial design stage to the etching process itself.

What Are The Differences Between Chemical Etching and Water Jetting?

While both are “cutting” processes, they achieve their results in fundamentally different ways.

| Feature | Chemical Etching | Water Jetting |

| Process Type | Chemical dissolution | Abrasive mechanical erosion |

| Tooling | Digital/Phototool | Physical nozzle and abrasive feed system |

| Contact | Non-contact | Contact |

| Heat | Cool process | Cool process, some heat from friction |

| Material Stress | None – intrinsic properties remain unchanged | High localised stress can cause delamination in laminates |

| Burrs | Burr-free and stress-free | Can create burrs, especially with softer metals |

| Tolerances | Extremely tight | Good, but wider than chemical etching |

| Edge Quality | Smooth, clean, and perpendicular | Textured, matte finish |

| Lead Time | Very fast for new designs | Fast |

| Best For | High-volume, ultra-thin, complex, fragile parts | Thick plates, prototypes, a wide range of materials |

Key Water Jetting Disadvantages

Water jetting is an incredibly versatile technology, ideal for cutting thick materials in a wide array of materials. However, its mechanical, abrasive nature leads to several inherent disadvantages that can be critical for precision metal part production.

The Burr Problem

The abrasive stream can push material aside and leave a micro-burr on the bottom edge of the cut. While techniques and newer machines can minimise this, deburring is often a necessary secondary operation. This adds time, cost, and the risk of damaging delicate parts. Chemical etching produces no burrs, eliminating this entire post-processing step and its associated costs.

Taper and Kerf Width

The waterjet stream is not perfectly cylindrical. It is slightly wider at the inlet than the outlet, which can create a minimal taper (V-shaped cut) in thicker materials. More importantly, the kerf (the width of the cut) is significant. A typical waterjet kerf is between 0.5mm and 1.5mm, meaning a substantial amount of material is turned into waste with every cut. Chemical etching, however, has a much finer tolerance. Because the etchant dissolves metal laterally, the gap between parts can be incredibly small (often less than the material thickness), enabling unparalleled material utilisation and nesting efficiency.

Mechanical Stress and Delamination

The immense force of the waterjet stream (which can be over 50,000 psi) impacts the material. This can work-harden the edges and, most critically for laminates or heat-treated metals, can cause delamination or micro-fractures. These are often invisible to the naked eye but can compromise the part’s structural integrity and fatigue life. Chemical etching is a stress-free process, making it the only viable option for critical components, such as springs, electrical contacts and medical implants.

The Abrasive Contamination Issue

Garnet abrasive is embedded in the cut surface. For many applications, this is irrelevant. However, for parts used in cleanrooms, aerospace or medical devices, this particulate contamination is unacceptable. Thorough cleaning is mandatory. Chemically etched parts emerge from the process clean and contaminant-free, often only requiring a simple passive rinse.

Limitations with Extremely Thin Materials

Water jets excel with thickness but struggle with extreme thinness. Chemical etching, on the other hand, is the master of thin metals. It can consistently and reliably produce parts from materials microns thin, with no distortion or stress.

Why Chemical Etching Is a Superior Water Jetting Alternative

Given these disadvantages, chemical etching emerges as the perfect alternative for specific applications. Its unique advantages solve the very problems that water jetting creates.

Unmatched Complexity Without Cost Penalty

With water jetting, complexity costs time. Intricate designs with thousands of tiny cuts or sharp internal corners require longer programming and cutting times. The physical nozzle also has a limitation on how tight a corner it can make. Chemical etching has zero cost for complexity. Whether your design is a simple washer or an incredibly complex mesh with thousands of intricate openings, the cost is the same. The phototool is just as easy to create for either design, and the etching process happens simultaneously across the entire sheet.

Perfect for High-Volume Production

Water jetting is a serial process, it cuts one part at a time, one after the other. Chemical etching is a parallel process, so an entire panel containing hundreds or thousands of parts is processed simultaneously. This makes photochemical etching dramatically more scalable and cost-effective for medium to high-volume production runs.

Absolute Consistency and Repeatability

Once the etching process is dialled in for a specific material and thickness, every single part produced from that batch, and every future batch, will be identical. There is no tool wear, unlike a waterjet nozzle, which erodes over time, subtly changing the kerf width and cut quality, requiring monitoring and replacement.

Ideal for Delicate and Stress-Sensitive Components

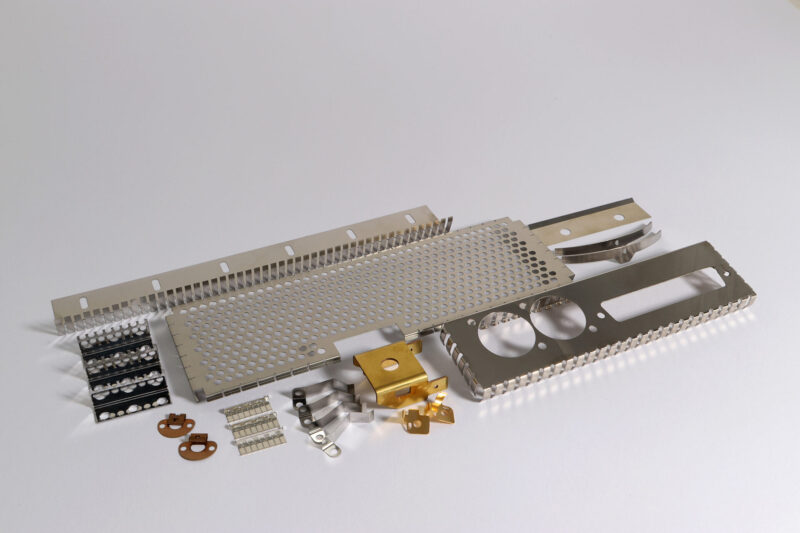

As a non-contact process that doesn’t use force, chemical etching is the go-to solution for manufacturing:

- Springs and contacts – Where retaining the material’s innate temper and flexibility is crucial.

- Medical blades and shims – Where absolute precision and no burrs are fundamental.

- RFI/EMI shields and meshes – Where thin, complex geometries must be produced without distorting the open areas.

- Lead frames and electronic components – Where the stress-free nature prevents future failure.

Rapid Prototyping

While a waterjet can quickly cut a one-off prototype, the part will have the characteristic waterjet finish and may also exhibit potential burrs. With chemical etching, your prototype is made using the same tooling and process as the full production run. This means your first article is truly representative of the final mass-produced part, not a rough approximation.

When Should You Use Water Jetting?

Water jetting is not obsolete. It is the right choice in several scenarios:

- Cutting very thick materials.

- Creating large-scale, low-volume parts like machine frames or single prototypes.

- Working with non-metallic materials like stone, tile, glass, rubber or composites.

The debate isn’t about which technology is better in a general sense, but which is the right tool for your specific application.

Choose water jetting if you need to cut thick plates, work with diverse materials and where ultimate precision and burr-free edges are not the primary concern.

Choose chemical etching if you are working with thin metals, require absolute precision, complex geometries, burr-free and stress-free parts, high volumes and impeccable consistency. It is the choice for high-value components where quality, reliability and material integrity cannot be compromised.

By looking beyond the initial allure of a familiar technology like water jetting, you can unlock the significant benefits of chemical etching, a process that offers a unique combination of precision, scalability and quality that is difficult to match with any mechanical cutting method.

Want to learn more about how chemical etching can help your next project? Speak to one of our experts today.