In the defence sector, component precision directly impacts performance and safety. Chemical etching meets the precise standards the sector demands. This advanced subtractive manufacturing process uses chemical agents to etch complex, burr-free components from thin metal sheets with exceptional accuracy. For engineers and procurement officers sourcing defence manufacturing components, understanding this technology is key.

Why Chemical Etching is Perfect for Defence

Chemical etching for defence excels where traditional methods fall short. It produces components without the mechanical stress, heat-affected zones, or micro-fractures caused by stamping or laser cutting. This results in parts with unaltered material properties and superior fatigue resistance. The process is ideal for prototyping and high-volume production, allowing for rapid, cost-effective design iterations without hard tooling. Crucially, it maintains absolute consistency part-to-part, a crucial requirement for mission-critical systems.

Benefits include:

- Burr-free & stress-free components

- Versatile material compatibility

- Unmatched precision & complexity

- Low-cost tooling & easy design changes

- Cost-effective prototyping to production

Where Defence Uses Chemical Etching

The defence and aerospace industries require precision metal components for a variety of critical systems, such as:

Aerospace & Avionics

Mesh filters for fuel and hydraulics, lightweight antenna components, EMI/RFI shielding gaskets and intricate parts for flight control systems.

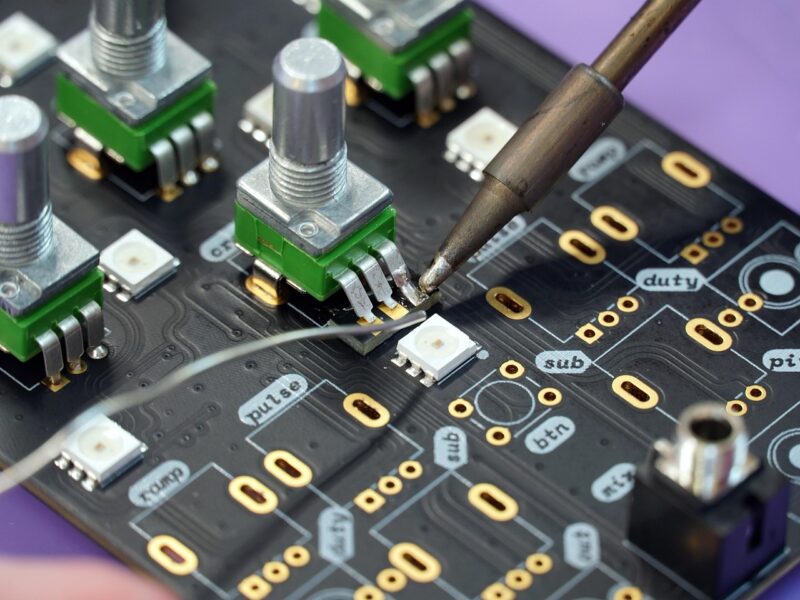

Electronic Warfare & C4I (Command, Control, Communication, Computer and Intelligence)

High-density lead frames, flexible circuits and shielding for advanced communication and processing equipment.

Armoured Vehicle Systems

Durable fuel cell meshes, precise sensor components and filtration elements for environmental control units.

Weapon Guidance Systems

Extremely precise apertures, shrouds and springs used in targeting and optical systems.

Identification & Safety

Intricate nameplates, serial plates and durable labels that withstand harsh environments.

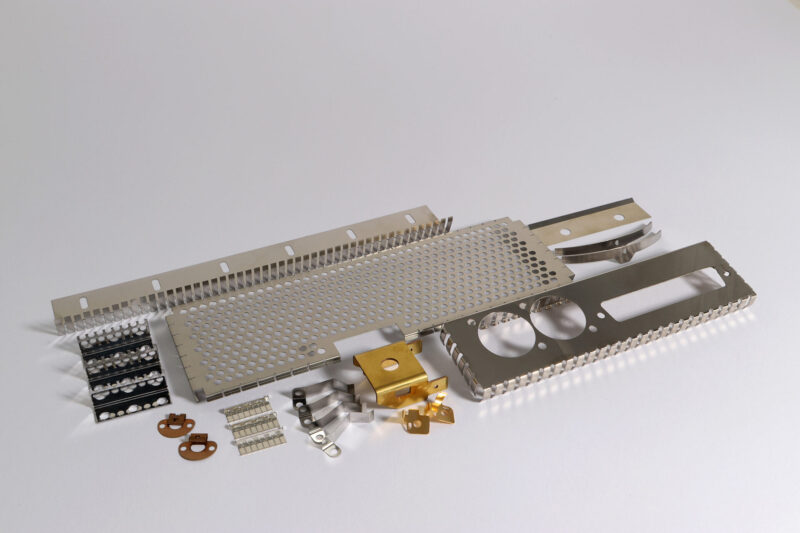

At Photofab, we have produced the following for the defence sector using chemical etching:

- Actuators

- Contacts

- Connectors

- Corporate Products

- Diaphragm

- Elements

- Enclosures

- Encoders

- Heat Exchanger Plates

- Fuel Cell Plates

- Brackets

- Filters

- Flat Springs

- Formed Components

- Instrumentation Dials

- Keypads

- Laminations

- Nameplates

- Intake Grilles

- Busbars

- Apertures

- Screening Cans

- Shims

- Solder Tags

- Spacer washers

- Spring Clips

- Springs

- Tear Bars

- Meshes

- Terminals

[The above list should be placed into a table]

Metals Used in Defence Applications

The defence industry relies heavily on a range of metals and materials, depending on the application. However, not all metals are suitable for photo and chemical etching. The most frequently used metals suitable for chemical etching include:

Steels

Mild Steel, Carbon Steel, Tool Steel, Spring Steel, Transit, Losil.

Stainless Steels

Austenitic (301, 302, 304, 316, S526, S527), Martensitic (321, 410, 420), Precipitation Hardened (17/7), Heat Resisting (309, 310).

Copper

Tough Pitch 101, Oxygen-free – High Conductivity.

Copper Alloys

Brass, Phosphor Bronze, Beryllium Copper, Nickel Silver, Ferry Constantan.

Aluminium Alloys

Aluminium, 7075, 7050, 7068, 7020, 6061, 5083, 5052.

Silver Alloys

Silver, Silver Alloys, Silver/Copper, Silver/Palladium, Silver Brazing Alloys.

Nickel Alloys

Nichrome, Mu Metal, Nickel Copper (70/30), Inconel, Nickel Brazing Foil, Invar, Alloy 42, Kovar, Radio Metal.

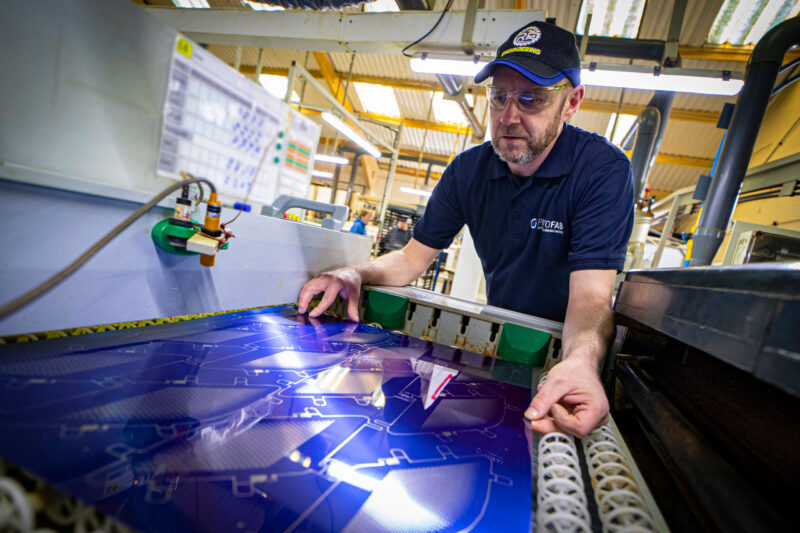

Why Choose Photofab

When sourcing etched metal components for defence, you need a partner that understands both the technology and the sector’s stringent demands. Photofab has 55+ years of experience serving the defence and aerospace industries. We combine expert engineering support with a certified, controlled manufacturing process. Our capability to produce complex, reliable components from prototype to production run ensures your projects meet precise specifications, deadlines and the highest quality standards. We deliver the precision that defence manufacturing demands.

With Photofab, you’ll benefit from:

- Fast lead times and free 24-hour quote

- Outstanding customer service

- Dedicated Account Manager from quote to delivery

- Bronze SC21 accreditation

- ISO 9001, 14001 and 45001 certification

- 98% on-time delivery rate

- Full traceability

- 55+ years of specialised experience in precision chemical etching

Need chemical etching for your next defence project? Get in touch today for a quote.