A Guide to Working with Metal Production Companies Like Us

For product design specialists creating metal parts, working with an expert chemical etching company like us can save money for the business you’re working with, uncover new designs and push the boundaries of your product.

Having a team of expert engineers that produce high-quality parts all year round can help you to discover new opportunities for both your part’s materials and designs.

Unlock revolutionary part design

This guide will walk you through how to maximise the output from these manufacturing partnerships and the benefits of working with a chemical etching.

Why work with expert metal production companies?

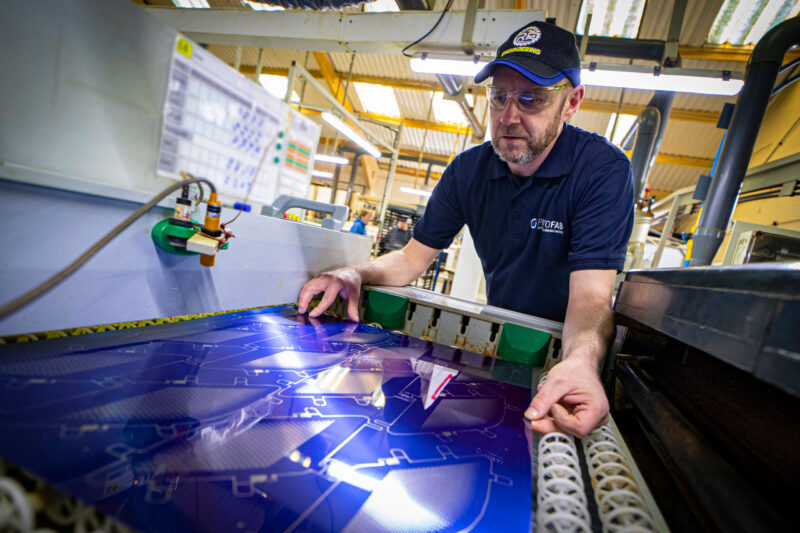

When you collaborate with a metal production company, you’re not just collaborating on your design process, you’re establishing a manufacturing partner for the production.

You’re partnering with experts who can bring your designs to life with precision and scalability.

Metal production involves processes with unique requirements and capabilities. Having a partner that understands the demands of exacting requirements in a multitude of industries is invaluable.

Why choose advanced manufacturing methods for fine parts

Using advanced manufacturing methods like chemical etching rather than traditional machining or stamping, chemical etching uses controlled chemical reactions to remove material and create parts. This is ideal for delicate or complex designs, as it imposes no stress on the material while maintaining exceptionally tight tolerances.

Design freedom is critical and a major benefit. Complex geometries, sharp corners, and intricate patterns that pose challenges for other methods are easily achievable with chemical etching. It’s also cost-effective, as design adjustments don’t depend on expensive tooling changes thanks to our in-house capabilities.

This is particularly beneficial during prototyping and iterative design phases, where chemical etching scales seamlessly from such processes to high-volume production. This ensures consistent quality every step of the way. For manufacturing product design specialists, it’s a smarter, more adaptable solution.

Detailed benefits of why product design specialists work with us

We hold the key for product design specialists tasked with achieving cutting-edge, high-quality products for prototypes. Our capabilities in chemical etching align perfectly with the exacting demands of modern product design teams, blending precision engineering, custom solutions and sustainable practices to deliver stand-out results.

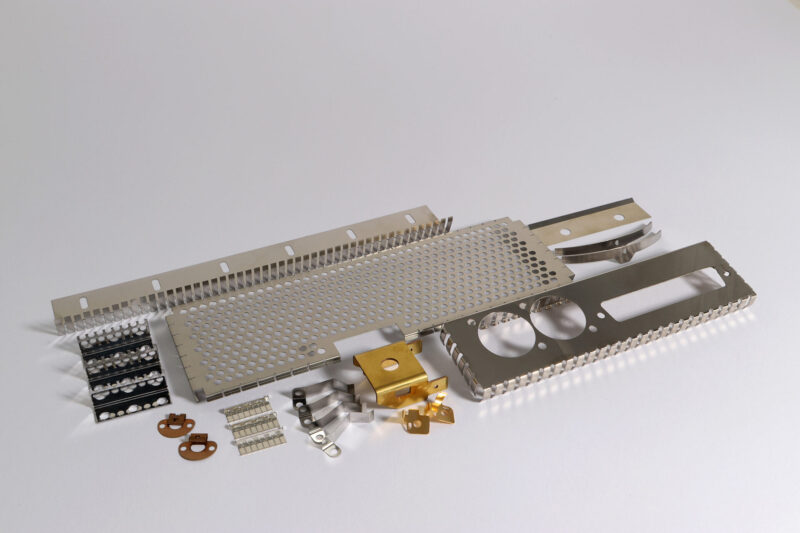

Precision and complexity scale

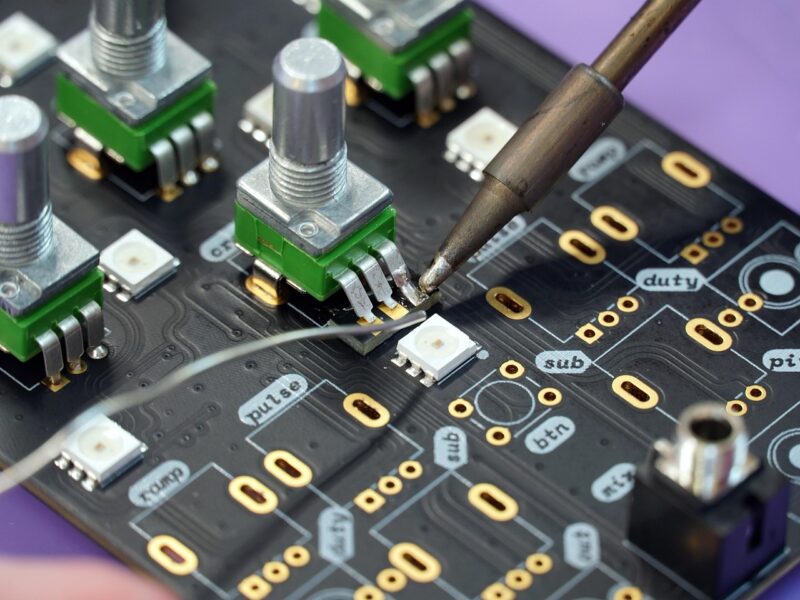

For design professionals, precision is non-negotiable, especially when working with intricate geometries or fine details. Our chemical etching process specialises in creating highly complex components with tolerances as tight as ±0.025mm. From intricate patterns for electronic circuitry to micro-scale components for medical devices, the etching technology onsite ensures designs are realised with uncompromising accuracy.

Whether you need a handful of prototypes or a large production run, the results are consistent, reliable, and meet the rigorous standards demanded by industries like technology and electronics.

Stress-free manufacturing for integrity

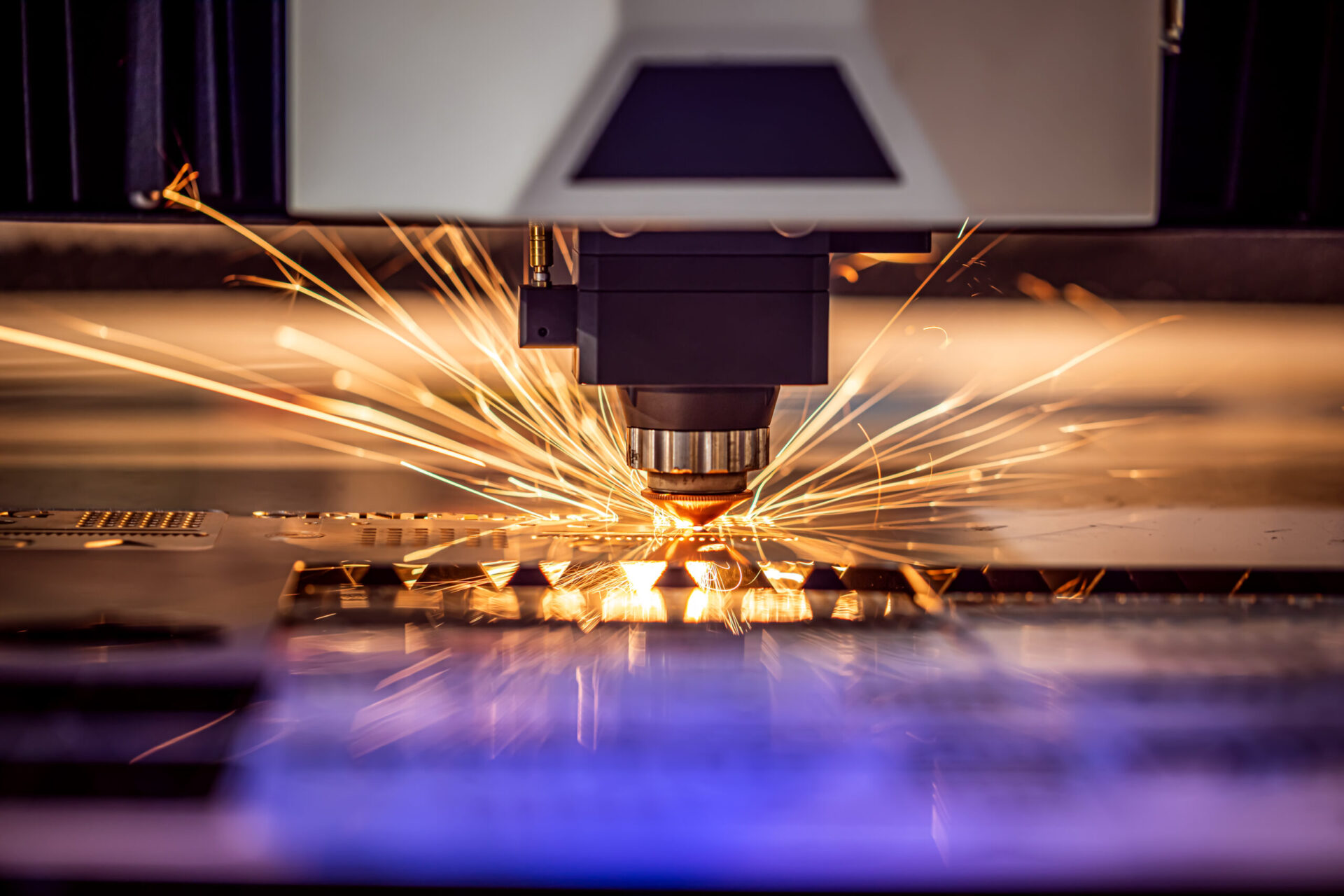

Mechanical stress and heat distortion introduced through traditional manufacturing methods like stamping or laser cutting can compromise material integrity. Product design specialists working on components that require exceptional durability or thin materials can rely on our non-invasive chemical etching process. By eliminating physical force and heat, it maintains the original properties of any material while achieving intricate, damage-free designs. This is particularly valuable for precision-critical applications where failure isn’t an option in new tech start up products.

Bespoke solutions to meet unique challenges

As your designs are likely never seen before, we put an onus on pushing design boundaries which generic manufacturing methods often fall short of. Whether your design calls for specialised materials like the lightweight aluminium or a hardier nickel alloy, or you’re tackling challenging geometries that others cannot realise, our expertise ensures your vision is brought to life.

Design teams can also benefit from their early-stage consultation services, where we can provide advice, if necessary, on material selection and manufacturability, optimising designs to reduce costs and improve efficiency.

Why it matters for design professionals

For design specialists, success hinges on balancing innovation with practical manufacturability.

Whether you’re navigating tight deadlines, working through iterative prototypes or aiming to meet demanding performance specifications, our chemical etching expertise ensures your designs are translated accurately and efficiently into tangible products.

Our expertise and genuine collaboration help transform even the most intricate designs into reality.

When tackling challenging designs, you often need a partner who really understands your vision, moving past ticking manufacturing boxes and working on overcoming design, material and creation hurdles.

Being able to refine prototypes quickly puts you in control of your deadlines, with a thorough yet flexible process, you need not worry about final production of your parts and prototypes.