Chemical Etching vs Stamping: Why Precision Wins Over Power

When manufacturing intricate components, choosing the right production method can make the difference between success and costly setbacks. In our recent series we’ve compared how chemical etching stacks up against laser cutting. Now it’s the time of chemical etching versus stamping.

Both are services that we offer, both require expert processes and both have their place in manufacturing processes.

Chemical etching is the superior choice for precision components, offering unmatched accuracy, material integrity and cost-effectiveness for complex designs.

Understanding the Fundamentals

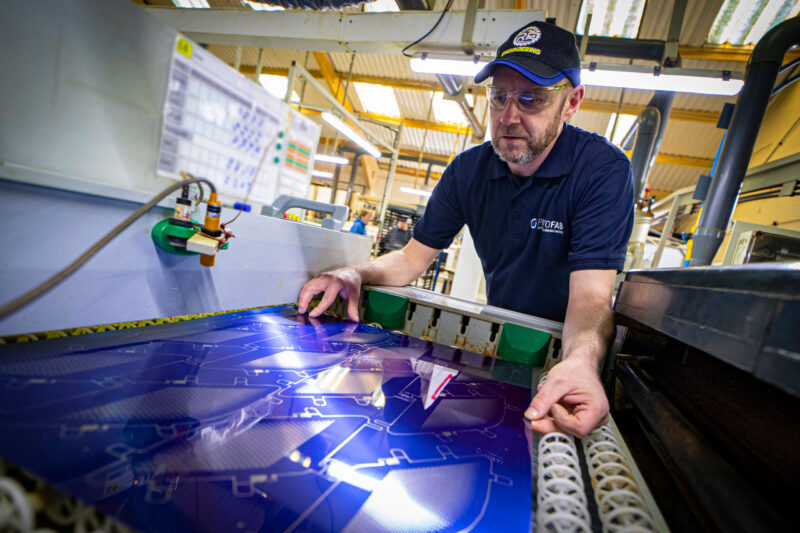

Chemical etching uses controlled chemical reactions to selectively remove material from metal sheets. This subtractive process relies on photoresist masks and etchants to create precise patterns. There’s no force applied.

Stamping uses mechanical force to cut and form materials. Dies and punches shape metal through compression, creating parts through deformation rather than material removal.

The fundamental difference lies in force.

Why Choose Chemical Etching Over Stamping

Precision

Chemical etching delivers tolerances as tight as ±0.025mm, consistently achieving accuracies that stamping struggles to match. This precision stems from patterns being photographically reproduced with microscopic accuracy.

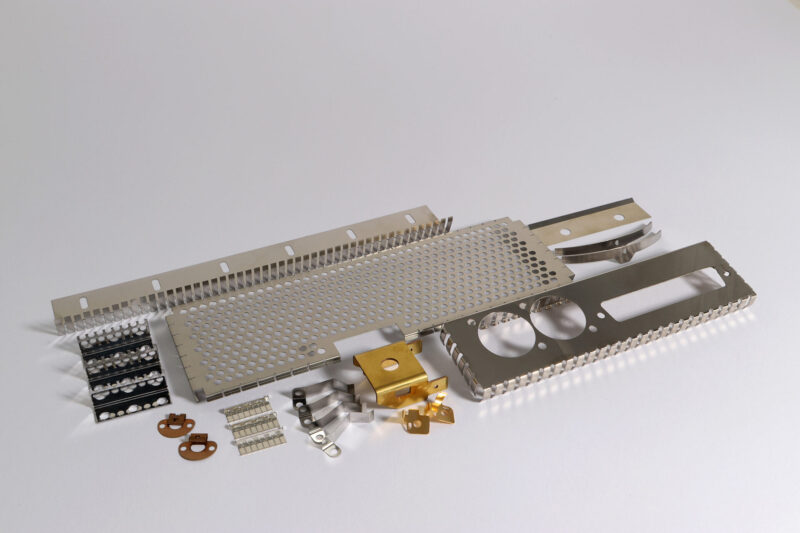

Complex geometries present another advantage. Chemical etching creates intricate patterns for honeycomb-style structures or detailed logos without additional tooling costs.

Material Integrity

Stamping applies significant mechanical stress, potentially altering material properties through micro-cracking. These stresses can compromise component performance, particularly in applications requiring consistent electrical or thermal properties.

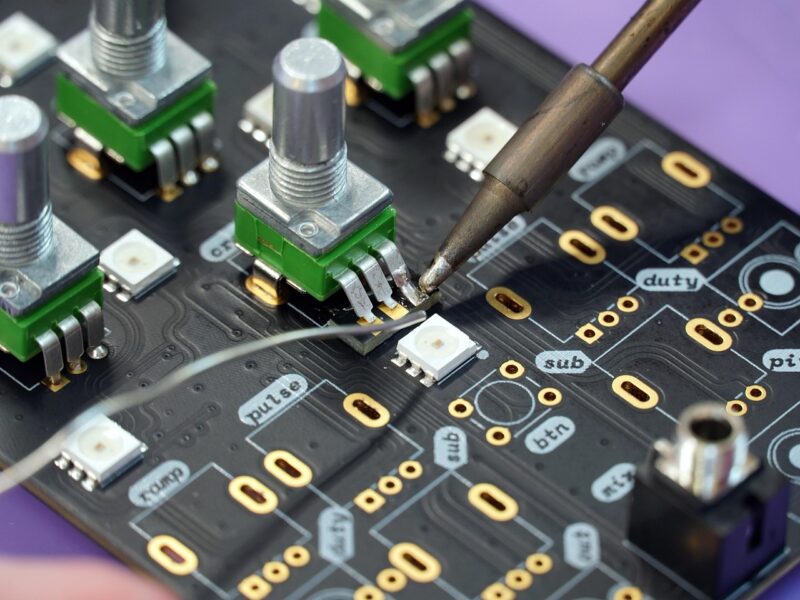

Chemical etching preserves material integrity completely. No mechanical force means no stress-induced changes to grain structure, hardness or conductivity making it a great option in electronic applications.

Cost-Effectiveness

Initial tooling costs reveal chemical etching’s economic advantage. Stamping is quite expensive and time consuming. Chemical etching requires minimal to no machining and has a low cost.

Low-volume production particularly benefits from chemical etching’s economics. Without amortising expensive dies across large quantities, chemical etching remains cost-effective for runs of hundreds or thousands rather than tens of thousands.

Design Flexibility

Stamping imposes significant design restrictions. Chemical etching eliminates these constraints. Any shape that can be drawn can be etched. Sharp corners, acute angles and closely-spaced features are no challenge for chemical etching but present issues for traditional stamping. Complex aperture patterns, precise spacing and intricate geometries become routine rather than problematic.

Surface Finish

Stamped edges often show burrs, tool marks or slight deformation requiring secondary operations. These imperfections can affect assembly, appearance or function, particularly in precision applications.

Chemical etching produces consistently smooth, burr-free edges with excellent surface finish. The controlled dissolution creates clean cuts without mechanical disturbance. Components are ready for use in the next phase of their assembly line.

Application Success Stories

Manufacturers increasingly choose chemical etching for shims and spacers, springs and fuel plates. The precision and repeatability prove essential for maintaining electrical performance across production runs.

Medical application manufacturers use chemical etching for surgical instruments, implantable components and diagnostic equipment. The ability to create complex patterns whilst preserving biocompatible material properties makes it indispensable.

Automotive suppliers use chemical etching for sensor components, gaskets, and decorative elements. The combination of precision, material integrity, and cost-effectiveness suits modern automotive requirements perfectly.

Making the Right Choice

Both chemical etching and stamping play valuable roles in manufacturing, each offering distinct advantages depending on your project’s needs. Stamping remains a reliable, cost-effective solution for straightforward, high-volume parts where speed and simplicity are the priorities.

However, for components that demand intricate detail, tight tolerances and preserved material properties, chemical etching truly shines. Its ability to produce complex geometries without introducing mechanical stress makes it the preferred option for applications where precision, flexibility, and design innovation are essential.

Reach out to our team now to discuss which suits your business needs.