Chemical Etching vs CNC Machining

When it comes to precision manufacturing, choosing the right metal cutting method is critical. Two popular methods – chemical etching and CNC machining – each offer their own strengths. But how do they compare, and which is best suited for your specific needs?

Here, we will explore the nuances of chemical etching vs CNC machining, analysing key factors like precision, material versatility, cost efficiency and scalability.

What Are Chemical Etching and CNC Machining?

What is Chemical Etching?

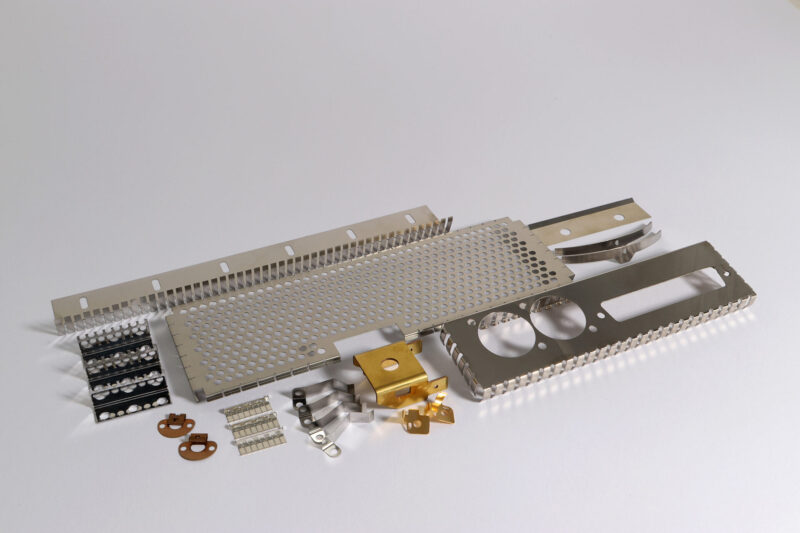

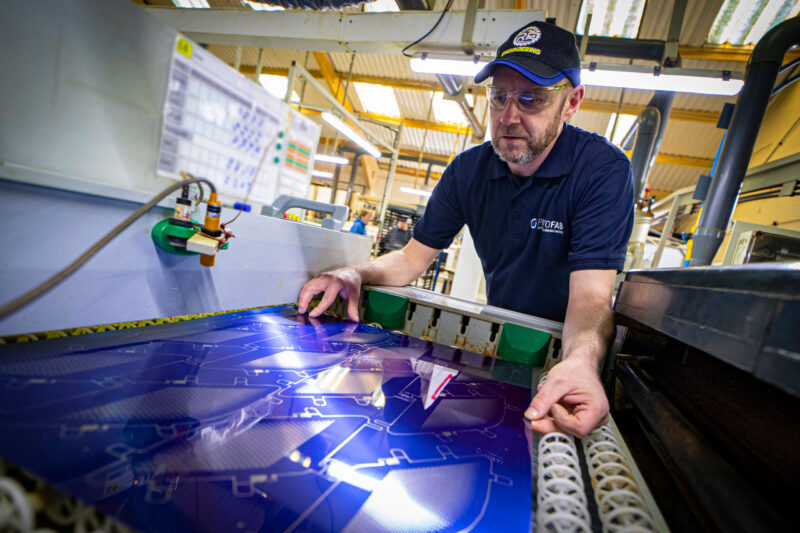

Chemical etching is a subtractive process that uses chemical solutions to remove material from metal sheets, enabling the creation of intricate and precise parts without mechanical stress. It is especially valued in industries where detail and material flatness are essential.

What is CNC Machining?

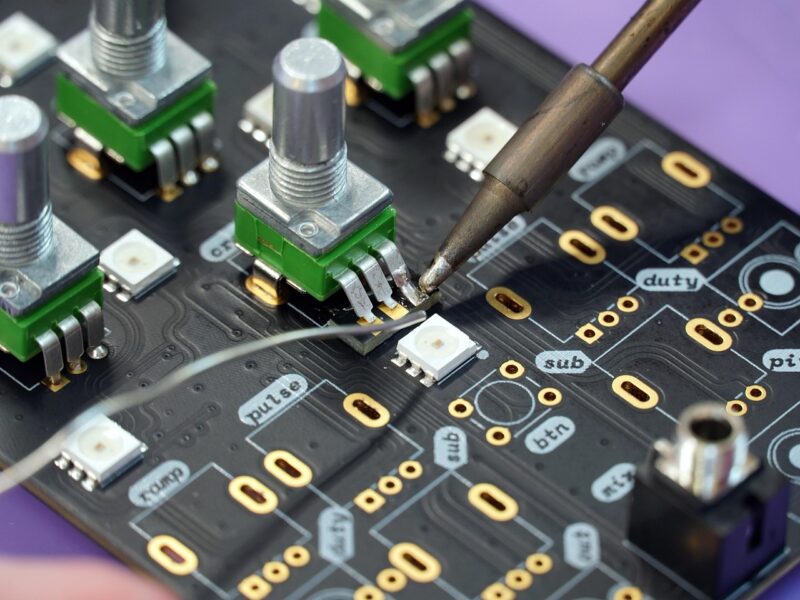

CNC (Computer Numerical Control) machining uses computer-operated tools to cut, shape or engrave components from solid materials. It is widely used for a variety of engineering and industrial applications due to its accuracy and flexibility with different shapes. Very fine features, micro holes and burr-free edges are harder and more expensive to get perfect when CNC machining.

Both methods are important in precision manufacturing, but their differences determine their suitability for specific jobs. Read about chemical etching or laser cutting here in our other blog in this series.

Key Comparison Factors for Chemical Etching v CNC Machining

To evaluate chemical etching vs CNC machining, consider these essential criteria.

Precision and Complexity

Chemical etching achieves extremely fine detail, ideal for intricate parts. CNC offers high precision but is less suited for very small or delicate features as it can drive up costs considerably.

Material Versatility

Chemical etching handles a wide variety of metals and thin alloys without damage. CNC works with many materials, but some metals and thin sheets can be challenging.

Cost Efficiency

Chemical etching keeps tooling costs low and remains affordable for small batches and complex designs. CNC costs increase for low volumes and intricate parts.

Speed and Scalability

Chemical etching moves quickly from prototype to mass production. CNC may require more setup and retooling, which can slow down larger projects.

Environmental Impact

Chemical etching uses closed-loop systems and generates minimal waste. CNC produces more scrap, uses more energy, and requires lubricants.

Why Choose Chemical Etching Over CNC Machining?

While both methods are valuable, chemical etching offers distinct advantages that make it the optimal choice in many scenarios:

Unmatched Precision for Complex Designs

If you’re working with intricate patterns or thin metals, chemical etching delivers results CNC machining cannot replicate.

Cost-Effective for Any Production Volume

Whether you need a single prototype or mass production, etching eliminates high tooling and setup costs, saving both time and money. There’s no need for time consuming hard tooling thanks to digital processes which means processes are typically more efficient and less expensive in comparison to CNC machining.

Material Flexibility

With compatibility across a wide range of metals and delicate alloys, chemical etching is the more versatile option. Minimal material waste makes it cost effective for thin metals.

Stress-Free Manufacturing

The non-contact nature of the process ensures there is no risk of deforming or damaging your materials, a common challenge for CNC tools.

Sustainable and Scalable

Modern chemical etching integrates environmentally friendly practices while offering seamless scalability for growing production demands. Multiple parts can be made from a single sheet of metal which reduces turnaround time and makes the possibility of quick prototyping and low-to-medium volume runs possible.

For industries demanding ultra-precise, intricate, and cost-effective metal parts, chemical etching is a clear winner. Its superior precision, design flexibility, and scalability place it ahead of CNC machining in many applications. While CNC machining has its merits in structural component work, the advantages of chemical etching, in terms of detail, versatility, and environmental sustainability, make it the go-to method for advanced manufacturing needs.

If you are exploring metal cutting methods and prioritise detail, efficiency, and sustainability, chemical etching is the solution you have been looking for.

Looking to bring your designs to life with unparalleled precision? Contact us to learn more about our advanced chemical etching solutions.