The Role Fine Parts Play in Day-to-Day Technology

We live in an age defined by technological innovation. Our devices are smarter, faster and more compact than ever before. This relentless drive towards miniaturisation and enhanced performance places immense demands on the components inside these devices. They must be incredibly precise, durable and often made from specialised materials without compromising their inherent properties.

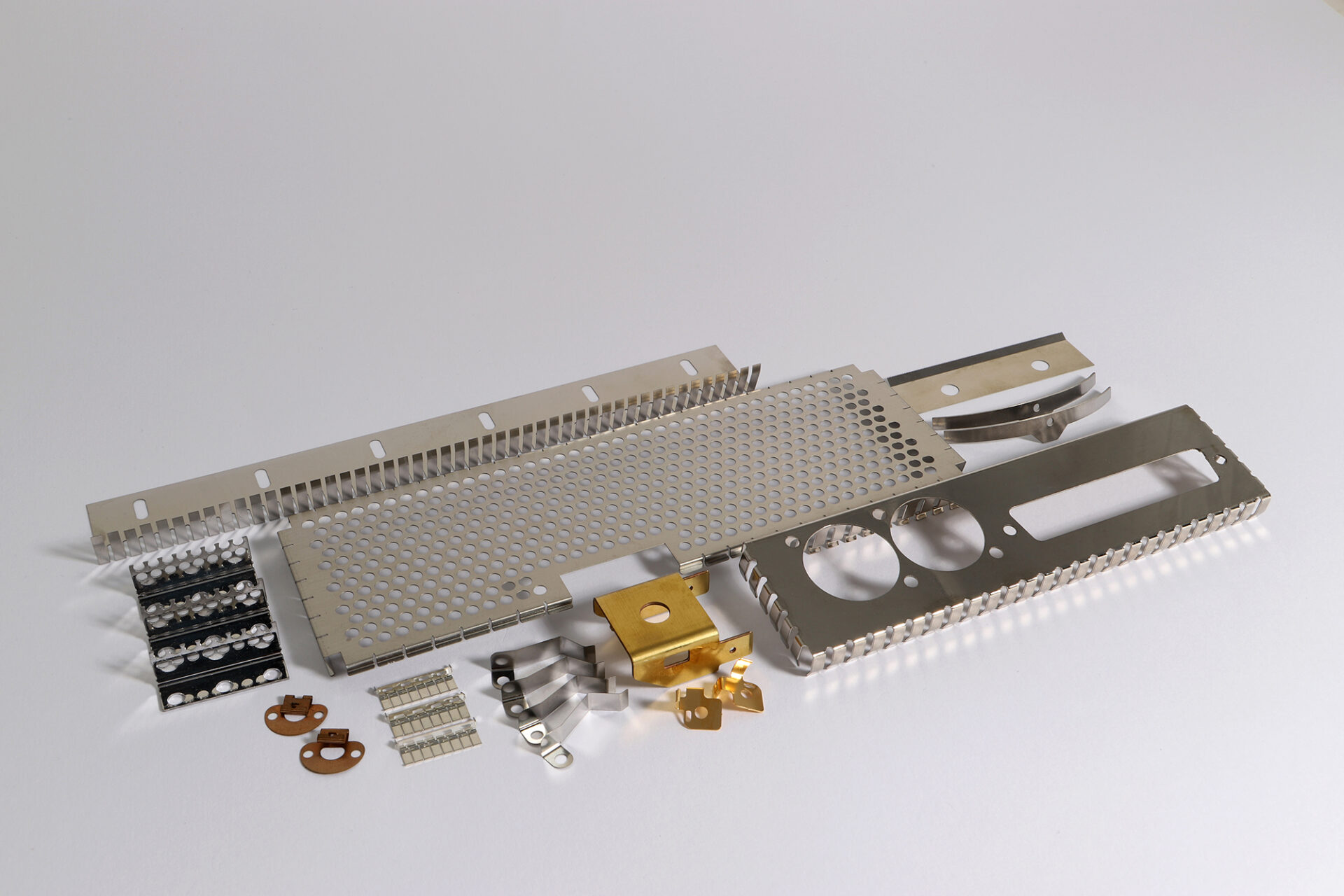

This is why fine parts play a big role in day-to-day technology. They are the filters, shields, contacts and connectors that form the essential backbone of our devices. And to create them, manufacturers increasingly turn to a versatile and efficient process known as chemical etching.

What are fine parts?

Fine parts, also known as precision metal parts, are components characterised by their complex geometries, thin material profiles and extremely tight tolerances. They are typically measured in millimetres or even microns and are fundamental to the operation of countless products.

Common examples of fine parts include:

- Metal meshes and filters – Tiny screens used in medical devices, fuel systems and aerosol filters.

- Electrical contacts and shields – Delicate components in connectors and EMI/RFI shielding that protect devices from interference.

- Lead frames – The skeletal structure inside microchips that connects the silicon die to the external circuit.

- Precision springs and contacts – Miniature springs in relays, sensors and micro-switches.

- Apertures and nozzles – Extremely precise openings used in inkjet printer heads and optical equipment.

The challenge in manufacturing these parts lies in producing them without altering the material’s properties, leaving no burrs and maintaining perfect accuracy. Traditional methods often struggle to meet these demands without incurring high costs or requiring secondary finishing steps.

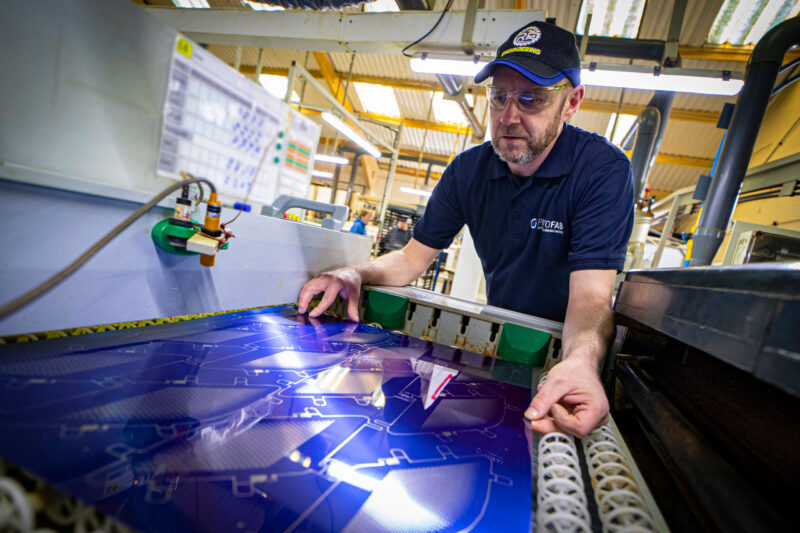

How does chemical etching work?

Chemical etching, also known as photochemical machining or milling, is a subtractive manufacturing process that uses a chemical bath (etchant) to cut complex patterns into metal. It’s a highly precise and repeatable technique that operates on a straightforward principle. The process involves several key steps: cleaning, lamination, exposure, development, etching, and finishing.

Head to our services page for an in-depth explanation of how chemical etching works.

What is chemical etching used for?

The uses of chemical etching are vast and span across nearly every high-tech industry you can imagine. Its ability to produce complex, stress-free parts without hard tooling makes it incredibly versatile. Uses include:

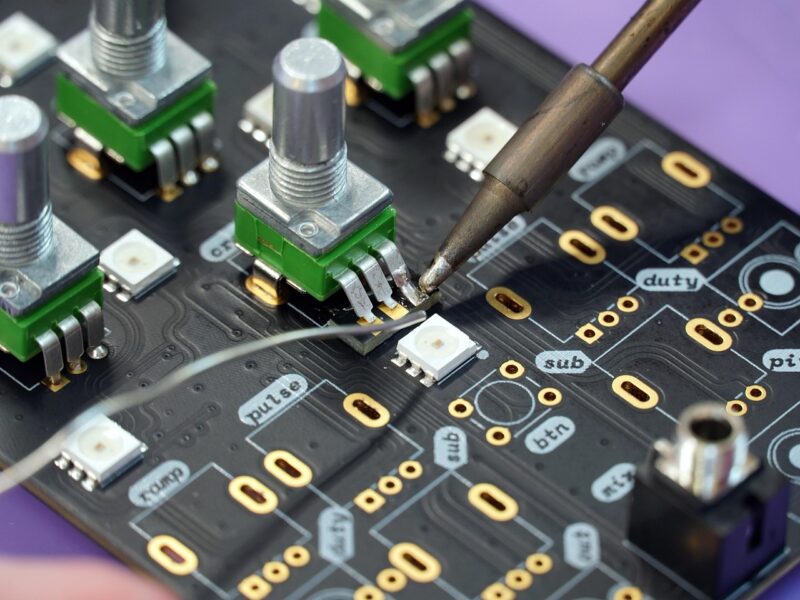

Electronics and Semiconductors

This is one of the largest application areas. Etching produces lead frames, connector components, EMI/RFI shielding cages and flexible circuits with absolute precision, which is critical for device reliability and signal integrity.

Medical Devices

The medical industry relies on etching for surgical tools, implantable components (such as bone scaffolds), biopsy plates and incredibly fine meshes for filters. The process can be validated to meet strict standards, ensuring biocompatibility and sterility.

Automotive and Aerospace

From anti-lock braking system (ABS) components and fuel injector screens to turbine blades and heat exchangers, chemical etching produces lightweight, high-strength parts that can withstand the extreme environments found in the automotive and aerospace industries.

Consumer Electronics

Chemically etched fine parts are found throughout the electronics sector. The tiny speaker grilles in headphones, the internal springs in a smartphone’s vibration motor, and the precision masks inside OLED displays are all made using chemical etching.

Renewable Energy

The process is used to create intricate parts for fuel cells, solar panel components and battery contacts, aiding in the development of greener technology and renewable energy.

Defence and Optics

Etching produces precise apertures, shadow masks and optical mounts for targeting systems, night vision equipment and scientific instruments used in the defence sector.

Essentially, wherever there is a need for complex, flat metal components that are difficult or expensive to make by other means, chemical etching provides a cost-effective and scalable solution.

Why chemical etching is better for manufacturing fine parts

When compared to traditional machining methods such as stamping and laser cutting, chemical etching offers a unique set of advantages that make it ideally suited for manufacturing fine parts.

No Mechanical Stress or Burrs

Etching is a stress-free process, unlike stamping, which can cause hardening and deform thin materials, or laser cutting, which can leave micro-burrs and heat-affected zones. The parts produced are completely burr-free and retain the material’s original characteristics.

Extreme Complexity

With etching, complexity does not increase cost. Intricate designs, fine details and complex geometries are as easy to produce as simple ones because the process is mask-based. Changing a design is as simple as modifying a digital photo tool, unlike the high cost and lengthy lead times associated with modifying hard stamping tools and dies.

Speed and Cost-Effectiveness for Prototyping and Production

Photo tools are digital and inexpensive, making prototyping incredibly fast and cheap. This enables rapid design iterations with minimal financial investment. The same efficiency translates to high-volume production runs.

Material Flexibility

Chemical etching works with a vast range of metals and alloys, including ones that are hard or brittle and would be difficult to stamp or machine, such as tempered spring steel and aluminium alloys.

Burr-free Edges

The isotropic nature of the etching process can produce high quality burr free edge profiles.

Top industries that benefit from chemical etching

To truly appreciate the impact of chemical etching technology, take a closer look at three fundamental industries that are dependent on chemically etched fine parts.

Medical Technology

The demands for precision, cleanliness and material integrity are fundamental. Etching produces:

- Stents and implants – Biocompatible, intricate mesh structures.

- Surgical instruments – Sharp, burr-free blades and jaws for robotic surgery tools.

- Diagnostic components – Precision plates for blood testing and DNA analysis equipment.

The ability to maintain material integrity and achieve absolute cleanliness makes etching perfect for the medical industry.

Aerospace and Defence

The aerospace and defence sectors require components that are lightweight, incredibly reliable and capable of performing in extreme conditions. Etching is used for:

- Turbine blades – Complex cooling holes are etched into blades to withstand extreme temperatures.

- EMI shielding – Critical for protecting avionics systems from electromagnetic interference.

- Lightweight structures – Etched mesh and panels provide strength without adding weight, a critical factor in aerospace design.

Telecommunications and 5G

The rollout of 5G technology requires a new generation of components that operate at higher frequencies. Etching produces:

- Waveguides and RF shields – Precise components that manage high-frequency signals with minimal loss.

- Antenna components – Complex patterns etched into thin foils for smartphones.

The precision and lack of heat distortion are essential for the communications industry to maintain signal integrity at these new frequencies.

Want to learn more about how chemical etching can transform the manufacturing of your fine parts? Speak to one of our experts to discuss your next project.

CTA: Talk to us about chemical etching

FAQs

What types of metal can be chemically etched?

Almost any metal can be etched, but some are more common than others. This includes stainless steel, aluminium, copper, brass, nickel, nickel alloys (like Inconel), titanium and beryllium copper.

What are the tolerances achievable with chemical etching?

Etching can hold very tight tolerances. A general rule is that the minimum achievable detail or slot width is typically equal to the material thickness. For example, on 0.1mm thick material, you can achieve details and minimum slots around 0.1mm. Tolerances generally are ±10% of the material thickness.

Is chemical etching an environmentally friendly process?

Modern chemical etching providers operate within strict environmental regulations. The chemicals used are carefully controlled, and spent etchant is often regenerated and recycled in a closed-loop system. The process generates less waste than mechanical processes as there is no tool wear and the raw material can be nested with extremely high efficiency.

How does the cost of chemical etching compare to stamping?

For complex parts, prototypes and low-to-medium volume production, etching is almost always more cost-effective due to its negligible tooling costs and faster turnaround times. The total cost of ownership is often lower with etching when you factor in the absence of secondary deburring operations.