In defence and aerospace manufacturing, component failure is not an option. Whether destined for electronic warfare systems, guided weapons platforms, or next-generation avionics, every part must satisfy rigorous defence application standards without exception. Yet for procurement leaders and design authorities, the challenge remains: how to ensure components meet defence manufacturing standards without delays, rework or compliance risk.

The answer is selecting a manufacturing partner, such as Photofab, that provides certainty:

- Certainty through absolute defence component traceability.

- Certainty through stress-free processing that preserves material integrity.

- Certainty through proactive defence quality assurance that satisfies the most demanding aerospace and defence compliance frameworks.

This is where Photofab thrives as a strategic partner to defence and aerospace primes, delivering photochemically etched components engineered for the most unforgiving environments.

The Cost of Non-Compliance in Defence Supply Chains

A single batch of non-compliant parts can trigger supply chain delays, contract penalties and (in worst-case scenarios) platform downtime. Unlike commercial manufacturing, where minor deviations might be waived, defence application standards demand a forensic-level of accountability.

For businesses operating under DEF STAN, AECMA or NADCAP frameworks, achieving consistent aerospace and defence compliance is a necessity.

Key Regulatory Bodies in Defence Manufacturing

To meet defence manufacturing standards, suppliers must align with governing bodies that set standards for both material behaviour and process control. In the UK and NATO-aligned markets, the dominant frameworks include:

- DEF STAN (Defence Standards) – UK-specific requirements for military equipment

- AECMA (European Association of Aerospace Industries) – Frequently referenced for aerospace and defence interoperability

- SAE International (AMS Specifications) – Invoked for material properties in defence hardware

- NADCAP – Increasingly expected for special processes in defence supply chains

Photofab’s quality infrastructure is structured to satisfy overlapping aerospace and defence compliance requirements simultaneously, eliminating the inefficiency of sequential approvals.

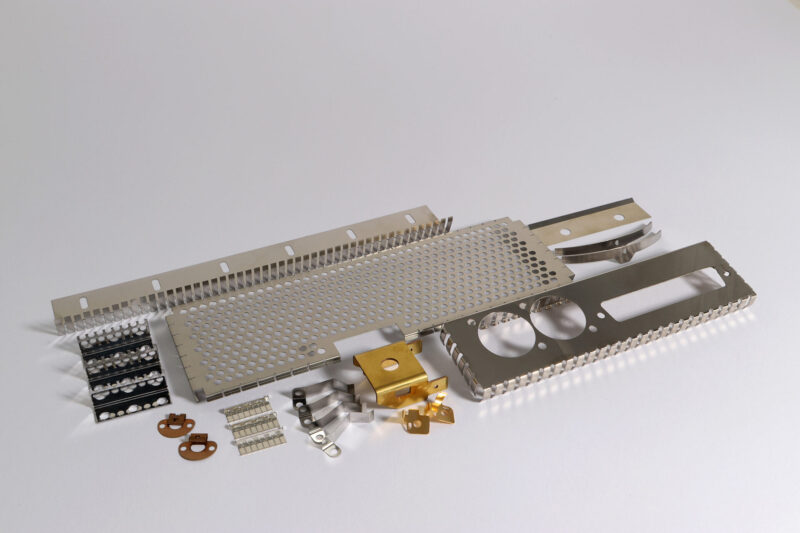

Key Metal Defence Application Standards & Specifications

Defence application standards rarely operate in isolation. A bracket inside a radar system faces different thermal and vibrational loads than a shim inside a small arms sight. Consequently, commonly invoked specifications include:

- BSI standards for dimensional verification methods

- MIL-SPEC derivatives for corrosion-resistant steels

- ASTM references for mechanical property verification

Where photochemical machining excels is in its ability to hold these defence application standards without inducing stress or heat-affected zones.

Common Material Requirements in Defence Applications

Defence manufacturing standards frequently mandate specific alloys known for predictable failure modes and environmental resistance. Stainless steels (particularly 302, 304 and 316), beryllium copper and titanium alloys dominate the sector. However, the presence of the correct alloy is insufficient. Defence quality assurance demands that the material behaves as specified post-processing.

This is a critical distinction. A material certificate confirms what entered the building. Defence component traceability confirms what left the building, and whether the manufacturing process compromised the substrate.

Photochemical etching, a cold-forming process, preserves the original grain structure and corrosion resistance of defence-grade alloys. Engineers do not have to choose between complex geometry and metallurgical integrity.

Defence Component Traceability

Defence component traceability is frequently misunderstood as simply retaining a delivery note. In modern defence manufacturing, traceability means lot-level segregation, retention of chemical certification and digital thread visibility.

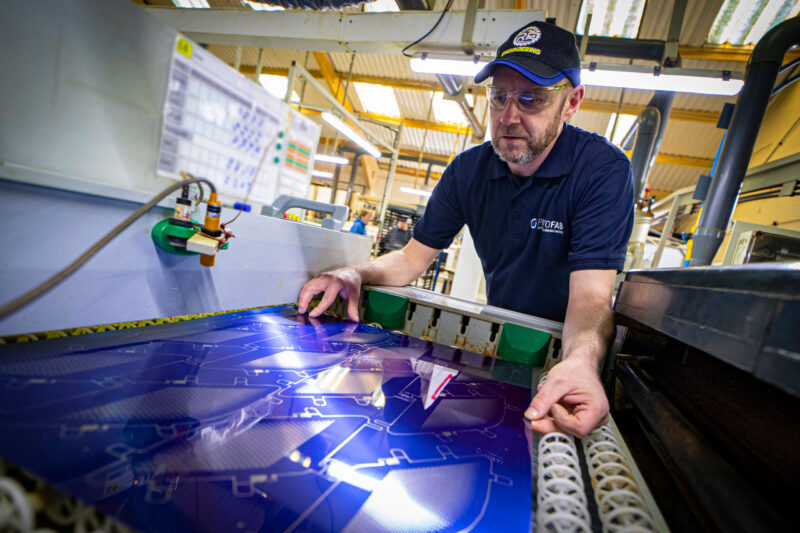

For Photofab, defence component traceability begins at material receipt and continues through imaging, etching and inspection. Batch numbers are retained. Process parameters are logged against specific purchase orders. If a query arises six months after delivery, the manufacturing record remains fully attributable.

For defence primes facing increasing scrutiny around supply chain provenance, this level of defence component traceability transforms defence industry compliance from a bottleneck into a competitive advantage.

The Advantage of Stress-Free Manufacturing

Mechanical stress is the invisible adversary in defence manufacturing standards. Conventionally produced components, which are stamped, laser-cut or machined, often carry residual stress induced by thermal or mechanical force. In benign environments, this may pass unnoticed. In defence applications, where thermal cycling, vibration and high G-forces are baseline conditions, latent stress becomes a liability.

Photofab’s photochemical etching process generates zero mechanical or thermal stress. The material enters the process as certified defence-grade alloy and exits with its grain structure, corrosion resistance and fatigue properties entirely intact.

For design engineers specifying components for UAV flight controls, radar positioning systems or armoured vehicle electronics, specifying Photofab means removing risk.

Defence Quality Assurance

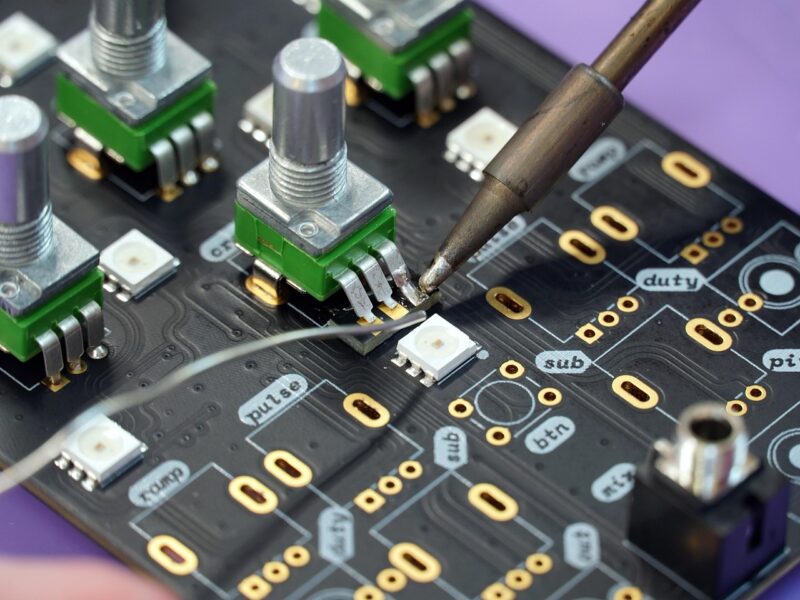

Defence quality assurance, correctly implemented, treats quality as a process attribute. Photochemical etching aligns with this philosophy.

Because the process is digitally-driven, variability between parts is minimal. Automated optical inspection (AOI) systems verify critical features against CAD source data, not subjective visual benchmarks. This shift from reactive inspection to proactive process control is what enables Photofab to deliver defence industry compliance without delay or rework.

For primes operating under AS9100 or NADCAP frameworks, this approach to defence quality assurance ensures compliance is engineered into every etch line rather than inspected at the end.

Aerospace and Defence Compliance – A Unified Approach

The boundary between aerospace and defence compliance continues to blur. Commercial aerospace platforms increasingly incorporate defence-derived technology, while defence procurement borrows commercial best practice in quality management.

Photofab’s certified management system reflects this convergence. SC21 recognition and ISO 9001 provide the foundational framework, overlaid with defence-specific process controls that satisfy both sectors’ expectations. For OEMs operating across civil and military portfolios, this unified approach to aerospace and defence compliance simplifies supplier qualification and reduces audit fatigue.

Meeting Sector Demands

Defence industry compliance environments are not static. Material specifications are updated. Regulatory bodies issue revised interpretations. Supply chain disruptions demand rapid requalification of alternative substrates.

Photofab’s partnership model accommodates this fluidity. Because photochemical etching is tool-less, design iterations do not trigger lengthy requalification cycles. A component can move from a revised CAD file to a validated first article in days, not weeks (without deviation from defence application standards or defence manufacturing standards).

This agility is particularly valued in rapid prototyping and mid-life upgrade programs, where primes require manufacturing responsiveness without sacrificing the rigour demanded by defence quality assurance.

Beyond Procurement For A True Partnership

The defence manufacturing landscape rewards certainty:

- Certainty of supply

- Certainty of conformance

- Certainty of provenance

At Photofab, we manufacture certainty through stress-free etching processes that preserve material integrity, through digital defence component traceability that forensically links each component to its origin and through a compliance architecture that anticipates rather than reacts.

For defence and aerospace businesses seeking a strategic manufacturing partner capable of meeting the most demanding defence application standards and compliance requirements, the conversation begins here.

For more insight on how component precision directly impacts performance and safety, please explore our piece on why chemical etching is perfect for defence.