Precision Engineering in Hydrogen Technology

Advances in hydrogen technology open the doors for innovative manufacturing processes

Toyota has announced it has introduced a third-generation hydrogen fuel cell system into the development of the automotive industry’s push for sustainable energy solutions. Aiming to establish hydrogen as an essential player in green car manufacturing, this new fuel cell looks to improve fuel efficiency by 20% and enhance performance and cost-efficiency too.

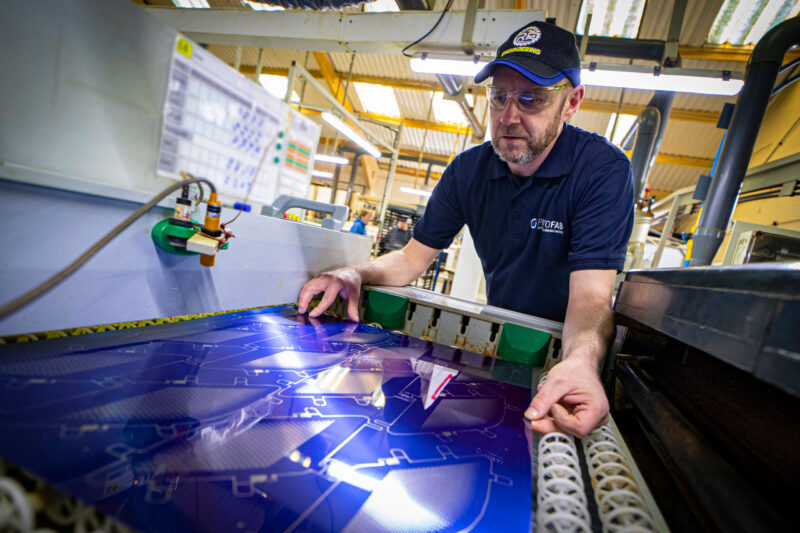

This puts the automotive industry at a crossroads. Design engineers must decide between traditional manufacturing methods or leaning on experts to create specialist, cost-effective parts quicker and more cost-effectively than ever before.

Managing Director here, Neil Shorten, looks here at how innovative manufacturing processes, specifically of fine parts, can revolutionise industries and businesses where change is paramount to success.

The Crossroads: Traditional vs. Innovative Manufacturing

The pressure to meet new sustainability standards is mounting, not just for governments but businesses and organisations, too. At this crossroads, the choice is between clinging to traditional manufacturing methods or adopting advanced, specialist processes designed to meet the evolving demands of scale while combining efficiency and quality with cost.

While traditional manufacturing methods, particularly of metal parts, can be familiar and established as the status quo, they can also struggle to keep pace with demands of growing markets – like EV production. This means that production can lose its competitive edge.

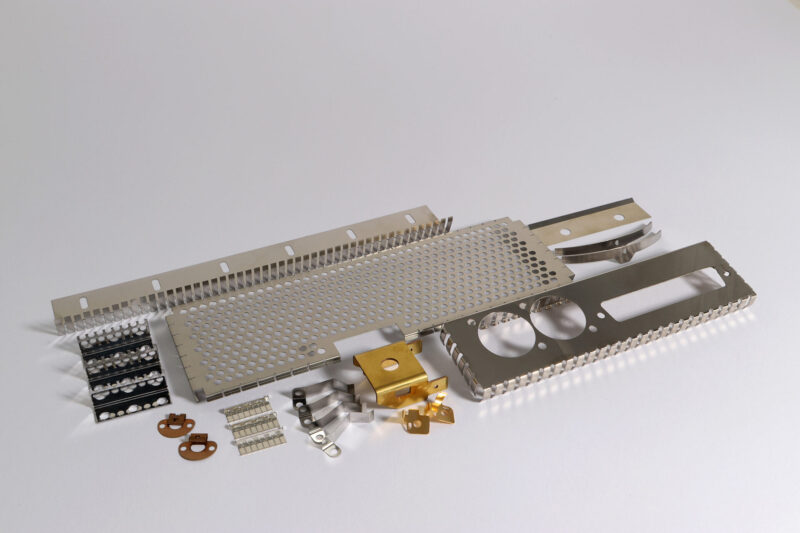

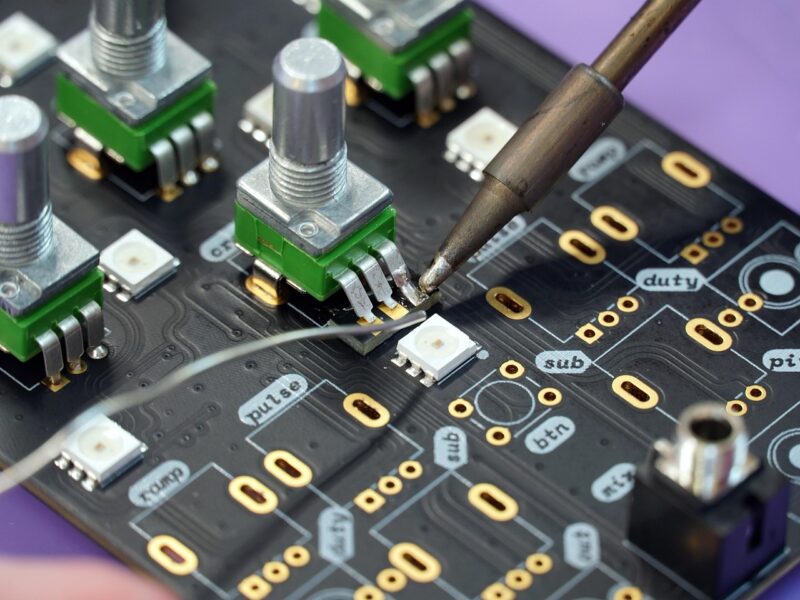

For companies producing parts for complex technologies like hydrogen fuel cell systems, it’s imperative that costs and waste are minimised to keep cost efficiency as high as possible. Precision, too, is a major hurdle with traditional methods tending to falter when creating finely detailed components required for complex technologies.

These limitations have set the scene for innovative manufacturing techniques to take centre stage. Processes like chemical etching offer engineers an opportunity to overcome these challenges while unlocking new possibilities.

They can produce intricate components with extreme accuracy, essential for modern designs that demand tight tolerances, adhering to strict guidelines.

Choosing innovation isn’t just about keeping up; it’s about remaining in the fast lane of a manufacturing landscape where speed and precision can define success.

The Role of Fine Parts in Industry Transformation

It’s no exaggeration to say that fine parts are essential to driving innovation in hydrogen technology.

As hydrogen fuel cells gain momentum as a sustainable energy source in the automotive industry, the demand for components engineered to exacting standards is at an all-time high. Every piece within these systems must be optimised for not just maximum efficiency but durability to not affect the drive of hydrogen-powered vehicles for example. A microscopic flaw in a fuel cell plate, for instance, could compromise the system’s performance or reduce its lifespan and lead to bad press for such a promising system.

It’s important to realise that automotive isn’t the only industry that demands high precision and the utmost reliability, and this shift isn’t new. Having manufactured parts for aerospace, green energy, food production and more, we understand the different hoops that different design engineers have to jump through. From micro-electromechanical sensors to turbine engine parts, finely crafted components can be used to their fullest potential in a variety of extreme conditions. Our chemically etched products are made to meet different levels of demands in performance and safety.

These scenarios underscore how critical fine parts are across sectors. Their influence lies not only in performance but in enabling industries to reach new heights of innovation. Specialists equipped with advanced manufacturing technologies, like chemical etching, are spearheading this transformation by delivering parts that meet the increasingly complex demands of modern applications.

By bridging the gap between precision and performance, fine parts drive progress in industries where excellence is not just desired—it’s required.

Toyota’s commitment to hydrogen technology, embodied in its third-generation fuel cell system, serves as a powerful reminder of the leaps industries can make when innovation is prioritised.

By investing in an open-minded manufacturing process and delivering substantial improvements in efficiency, performance and cost, this advancement echoes a broader call to action for manufacturers across sectors. The potential applications of this technology, ranging from passenger vehicles to commercial transportation, underline the versatility and necessity of open-minded solutions in tackling global sustainability challenges.

Fine parts, manufactured through innovative methods like chemical etching, are not just components; they are enablers of industry-wide evolution, from automotive and aerospace to medical and electronics. They allow businesses to meet modern demands without compromising on quality or efficiency.

As Toyota has shown, the intersection of precision and performance isn’t just a goal; it’s a catalyst for redefining what’s possible in a sustainable future. Now is the time for decision-makers to commit to this vision and champion green innovation.