Industrial spring and flat spring manufacturers

We are a world leading spring supplier with over 50 years of experience in metalwork. In this time, we’ve mastered the art of custom spring manufacturing for a variety of high pressure industries from aerospace to energy and optical to automotive.

Custom springs from Photofab

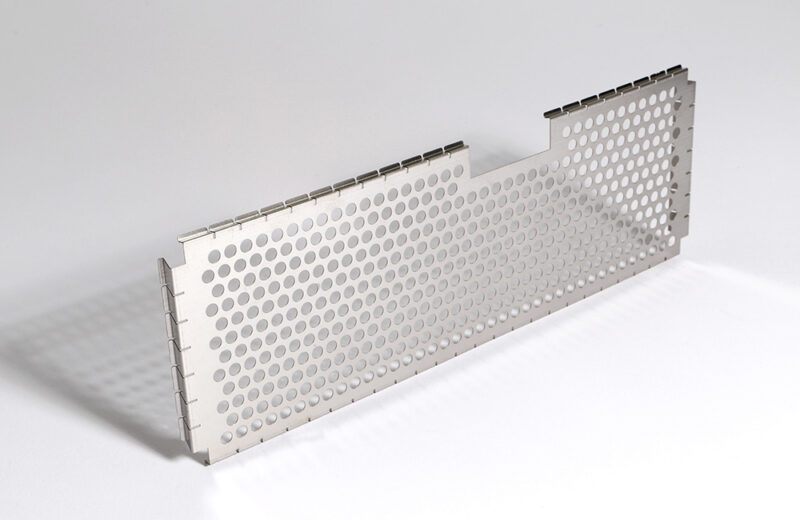

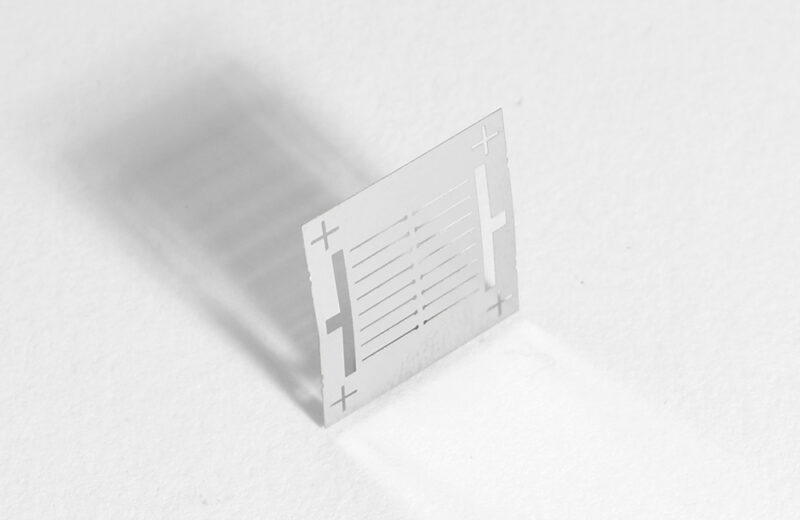

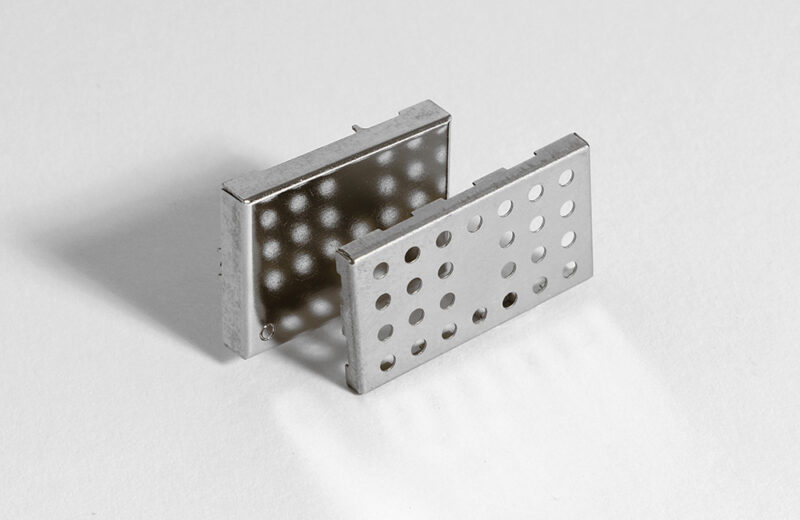

We provide flat springs, formed springs, strip springs and fine parts for springs.

Our manufacturing process is ideal for creating intricate and fine parts for springs from prototype to high-volume production. We deliver exceptional precision and rapid turnaround times, ensuring your project stays on schedule and within budget.

Ready to start your project?

Why choose photofab as your spring supplier?

Our experienced toolmakers can reverse-engineer components, sketch form tools by hand, and manufacture everything from contact and flat springs to bespoke one-off parts.

- Low-Cost Tooling: Digital tooling eliminates expensive and slow traditional tools.

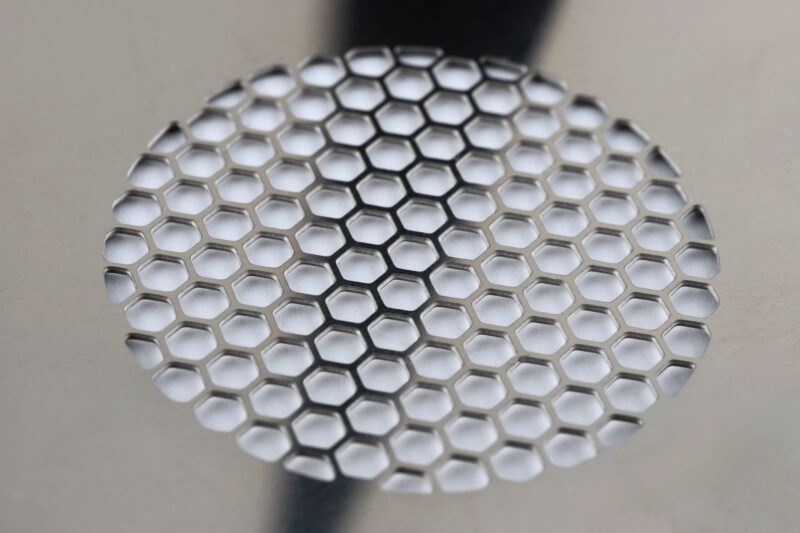

- Unmatched Precision: Create complex designs and fine apertures with high accuracy.

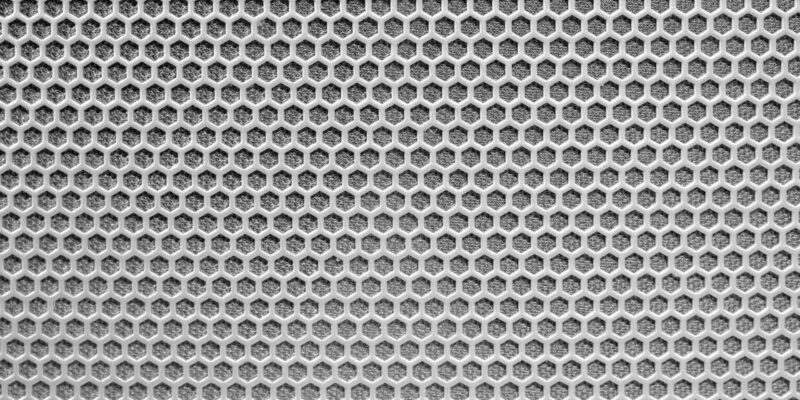

- Stress & Burr-Free Parts: Our process ensures integrity of metal for high-performance.

- Rapid Prototyping: Go from design to physical prototype quickly to boost development.

- Full Customisation: Choose from a range of metals to suit your design and demands.

- End-to-End Service: From design support to heat treatment and finishing, we manage the entire production process.

Your complete spring manufacturing partner

At Photofab, we provide more than just parts; we deliver a complete manufacturing solution tailored to you.

Extensive material selection

We can produce your springs from a wide variety of metals, including stainless steel, beryllium copper, bronze and nickel alloys. If your required material isn’t listed, our engineers will work with you to find a suitable solution.

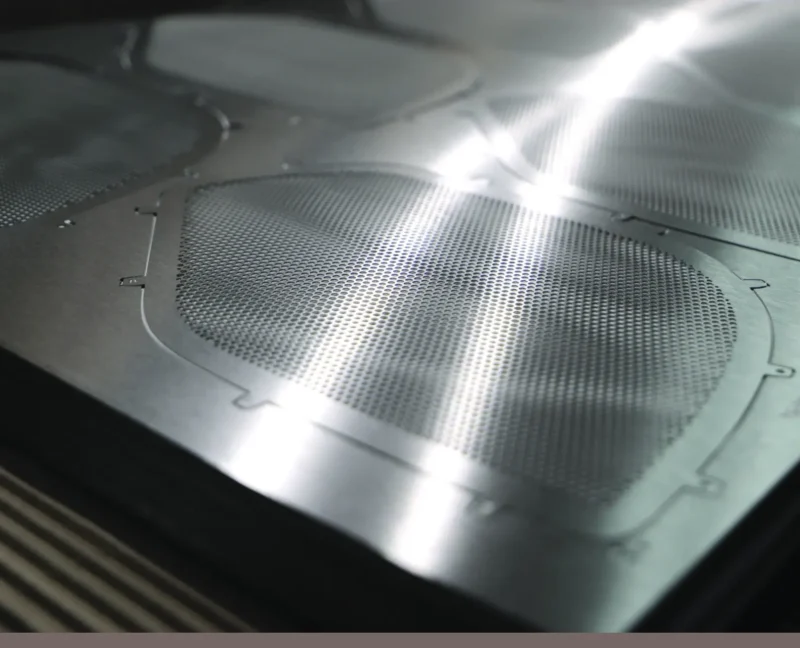

Heat treatment & forming

We offer specialised heat treatments like annealing, tempering and precipitation hardening to enhance the mechanical properties of your springs, improving durability and performance. After chemical etching, we can form the flat blanks into the final required shape using our universal or custom tooling.

dedicated support

From your initial enquiry, you will be assigned a dedicated account manager who will be your single point of contact during product development. They provide technical advice and ensure your project is delivered on time and to the highest standards.

Quality Springs from Photofab

A successful spring must be highly elastic and designed to absorb kinetic energy, usually in the form of vibrations. Photofab understands that springs need to be precision-made to fit custom components and meet required specifications. Our heat-treated, highly precise springs are able to lock a mechanical part into a fixed position.

There are many different types of springs used in industry, Photofab have been working closely with the spring manufacturing industry for over 50 years to produce a variety of flat and formed springs for use in many industries. Over that period of time, we have produced many different designs of strip springs using our world leading Chemical Etching process. By using this process, we are able to produce a blank that can be formed using either our in-house universal or customer specific form tools to produce the required formed shape.

You may be surprised to see the extremely fine detail we can etch into metal. In certain instances, these tolerances can even be improved! Photofab has been the world leader in Chemical Etching for over 50 years. We would be more than happy to work with you to produce springs to your exact needs. Please don’t hesitate to contact us, and our engineers will be delighted to speak to you about designing and prototyping springs (LINK – dedicated engineering), before moving into volume production, delivered in best-in-class lead times.

We can supply the springs heat treated, plated, and assembled giving you a finished spring from one source of supply. This reduces logistics time and therefore improving lead times further.

The benefits of etched springs with Photofab

- Low-cost tooling

- Customised parts – you design it – we make it!

- Heat treatments

- Various surface finishes available

- High volume capabilities

- High accuracy pieces

- Fine Apertures

- Burr-free & Stress-free manufacturing method

- Prototypes – fast turnaround to meet your needs

- Dedicated Account Manager

These facts along with short delivery times – sometimes in as little as five days or less, are the reasons so many companies turn to Photofab as their preferred supplier of flat springs. Get in touch with us today to join the growing number of manufacturers who rely on Photofab’s expertise to supply them with bespoke components.

start your production journey today

If you are looking to find a complete service include dedicated engineering to design and implement your solution, get in touch with us. You’ll be allocated your own dedicated account manager who is always on hand to advise and take care of everything for you. Call Photofab on 01480 226699 or contact us now to see how Photofab can add an extra dimension to your manufacturing project. Keep up to date by following us on LinkedIn and Twitter.

The benefits of

working with us

We are world leaders in the development of photochemical technology to produce intricately shaped components. We have produced over 80,000 different components over the years and are highly regarded for our chemical etching process. Our engineers offer many services, and will offer advice to improve the product and reduce the costs.

24-hour quotation service

Dedicated account managers

Rapid manufacturing service

Cost saving stock of uni-tooling

Etched fold lines for tool-free forming

Full manufacturing service and supply chain management

Access to manufacturing and technical advice and expertise

Quality accredited to ISO 9001, ISO 14001, ISO 45001 and SC21 Bronze

The Photofab difference

One of the key reasons Photofab enjoy its customer retention and longevity is the team of dedicated account managers. This ‘single point of contact’ throughout the whole process, ensures a personal service, and pride in the quality and reliability of the entire Photofab service.

Customers rely on their dedicated contacts’ understanding and in-depth knowledge of their specific requirements and know the highest standards will always be met using the most efficient and cost-effective methods.

This consistent customer service is the foundation of our customer loyalty and is maintained throughout every department and every stage of production. Put us to the test for your next project and call one of our account managers on 01480 226699 or use our customer enquiry form, we would love to hear from you.

start your production journey today

If you are looking to find a complete service include dedicated engineering to design and implement your solution, get in touch with us. You’ll be allocated your own dedicated account manager who is always on hand to advise and take care of everything for you. Call Photofab on 01480 226699 or contact us now to see how Photofab can add an extra dimension to your manufacturing project. Keep up to date by following us on LinkedIn and Twitter.

TAKE A LOOK AT OTHER

PRODUCTS FROM PHOTOFAB

To find out how we can help you

Get in touch today

FAQ’s

Formed Spring faqs

Formed springs are springs created by shaping a metal strip or sheet into a custom profile – rather than being coiled like traditional wire springs. They may be bent, folded or formed to match the geometry of the assembly in which they will be used.

Depending on your requirements, formed springs can be manufactured from a range of materials, including Stainless Steel, Carbon Spring Steel, Beryllium Copper, Phosphor Bronze – and other alloys if required.

Yes – at a specialist supplier, formed springs can be custom-designed from your engineering drawing, with precise tolerances, custom bends, folds and even fine detail using techniques such as chemical etching plus in-house forming tools.

Formed springs are used across a wide range of industries – including aerospace, automotive, electronics, medical and more – wherever bespoke spring shapes and precise tolerances are needed.

Flat Springs faqs

A flat spring is made from a flat strip of metal (rather than coiled wire). It stores mechanical energy by bending or flexing when a load is applied, then returns to its original shape — providing force or motion control in applications where space is tight or coil springs won’t fit.

Yes – like formed springs, flat springs can be custom-designed, stamped or cut from sheet metal, then shaped or contoured to fit specific assemblies. This makes them very versatile for bespoke engineering needs.

Flat springs often outperform coil springs where space is restricted – they can fit into thin profiles, deliver precise deflection control and handle repeated bending or flexing with durability. They also offer design flexibility, allowing manufacturing in various shapes, sizes and materials for tailored solutions.