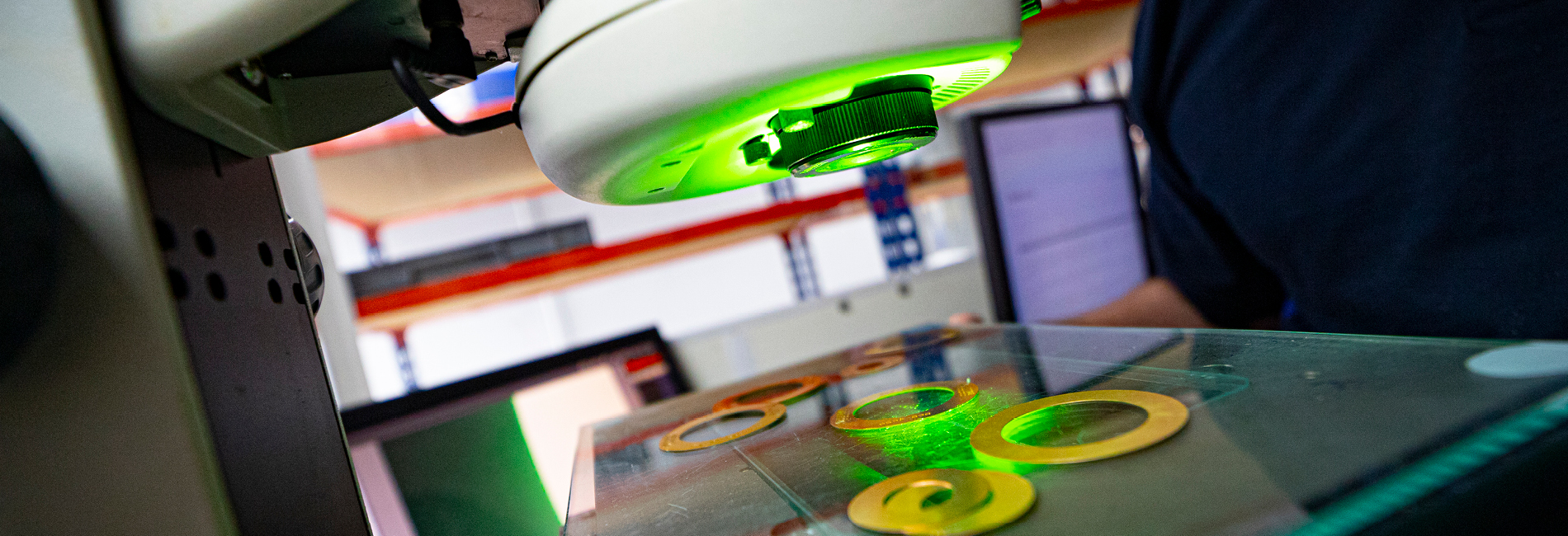

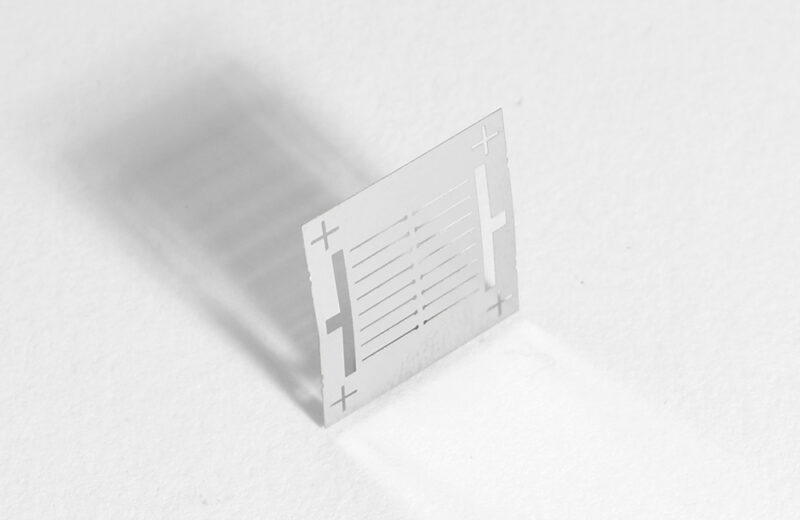

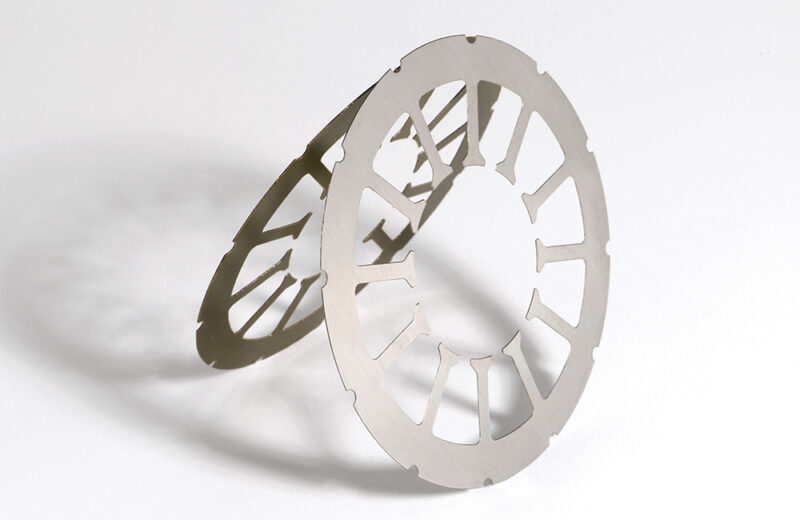

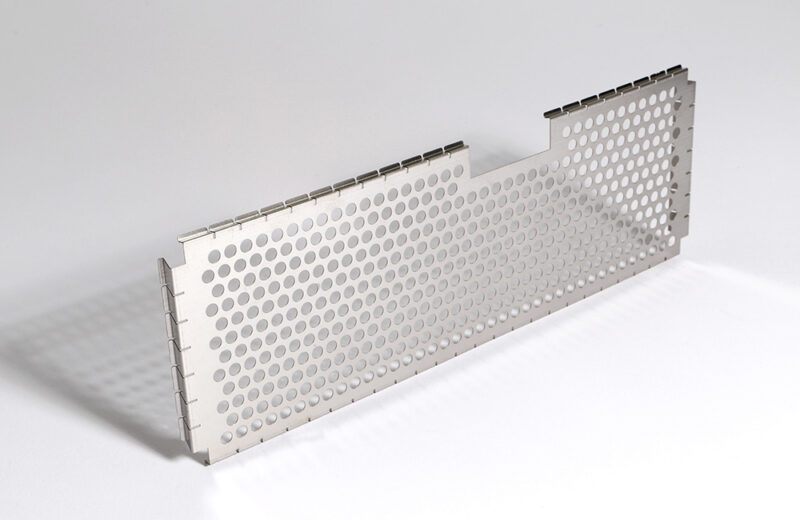

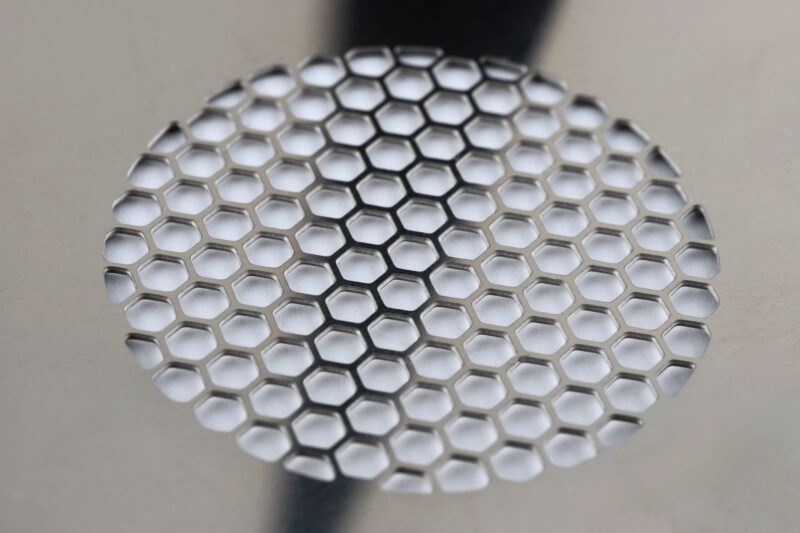

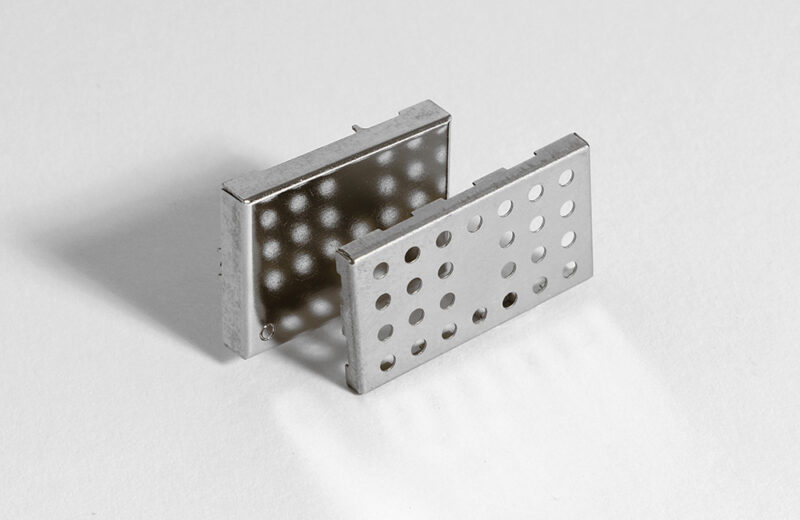

Photofab have over 50 years of experience in designing and manufacturing precision metal shims and spacers, offering low-cost tooling and manufacturing of custom, burr-free parts in a wide choice of materials. Metal shims are components that fit between two surfaces to improve the fit of the parts and reduce wear on them. They can be used to support, adjust, or provide a level surface. These important parts can extend the lifespan of equipment and are sought after in a variety of industries.

Photofab can be trusted to deliver these parts to the highest standard and to extend the lifespan of your equipment. Our shims are often used to absorb tolerances between two components, reducing incompatibilities. The whole manufacturing process is managed in-house by one of our experienced and technically trained account managers.

For more information on how we can reduce your costs & improve lead time contact our dedicated account managers on 01480 226699 or email enquiries@photofab.co.uk.

Our experience with metal shims and spacers

Photofab commonly manufactures metal shims and spacers from as thin as 0.01mm up to 1.2mm. These are produced to a very high tolerance and can be available in a wide selection of metals, including popular materials such as stainless steel, mild steel and carbon steel. If your desired material is not listed, please do not hesitate to contact us and we will work with you to produce a solution. You can trust Photofab’s experts to deliver outstanding service and quality, no matter the product or process.

| Metal Type | Available Alloys |

| Stainless Steel Shims and Spacers | 301, 302, 304, 316 |

| General Steel Shims and Spacers | Mild Steel, Carbon Steel, Spring Steel |

| Nickel Alloy Shims and Spacers | Mu Metal, Inconel 42/600/601/702/705 and Kovar |

| Copper and Copper Alloy Shims and Spacers | Brass, Oxygen-free Copper, Phosphor Bronze, Beryllium Copper, Nickel Silver |

Why use Metal Shims and Spacers?

Metal shims and spacers are considered essential components in many industries because of their impact on reducing wear and improving machine lifespan. Photofab can produce these components in metal, the main advantage of doing so is that they can be specifically designed to meet precise requirements, but also have a higher temperature and corrosion resistance than other materials, ensuring a longer lifespan. Photofab’s metal shims and spacers are the part of choice for many of our customers.

The benefits of milling shims and spacers with Photofab

- Burr-free & stress-free manufacturing method

- High temperature and corrosion resistance

- Single piece up to high volume

- Fully traceable and managed in-house

- Very high tolerance

- High accuracy and consistency

- Cost effective tooling and manufacture

- Fast turnaround, from 24 hours

- ISO 9001, 14001, 18001 and SC21 accredited

- Dedicated Account Manager

These facts along with short delivery times – in five days or less, are the reasons so many companies turn to Photofab as their preferred supplier. Get in touch with us today to join the growing number of manufacturers who rely on Photofab’s expertise to supply them with bespoke components.

DEDICATED engineering

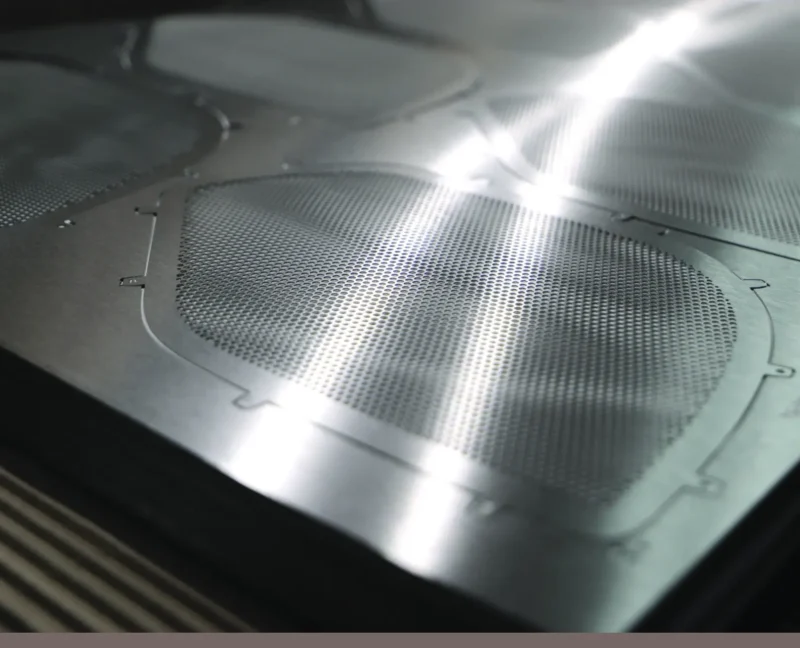

Photofab understands the importance of skilled engineering when designing components and putting them into production. Therefore, we have heavily invested in a dedicated secondary engineering unit, the aim of this is to offer an even greater service and flexibility to our customers.

Originally set up to provide an in-house solution to support the etching division, it has proven so popular with our customers that Photofab are now offering toolroom, forming and finishing as stand-alone services. This means our customers now have access to a new level of flexibility – enjoying the convenience of full-service manufacture or pick and choose services to suit them. It truly is a complete service from Photofab.

Photofab continues to offer cutting-edge services and outstanding lead times, and we can do so because of continuous investment in our people and our processes, leading to class-leading output and lead times – including our rapid 24 hour turnaround service.

The benefits of

working with us

We are world leaders in the development of photochemical technology to produce intricately shaped components. We have produced over 80,000 different components over the years and are highly regarded for our chemical etching process. Our engineers offer many services, and will offer advice to improve the product and reduce the costs.

24-hour quotation service

Dedicated account managers

Rapid manufacturing service

Cost saving stock of uni-tooling

Etched fold lines for tool-free forming

Full manufacturing service and supply chain management

Access to manufacturing and technical advice and expertise

Quality accredited to ISO 9001, ISO 14001, ISO 45001 and SC21 Bronze

The Photofab difference

One of the key reasons Photofab enjoy its customer retention and longevity is the team of dedicated account managers. This ‘single point of contact’ throughout the whole process, ensures a personal service, and pride in the quality and reliability of the entire Photofab service.

Customers rely on their dedicated contacts’ understanding and in-depth knowledge of their specific requirements and know the highest standards will always be met using the most efficient and cost-effective methods.

This consistent customer service is the foundation of our customer loyalty and is maintained throughout every department and every stage of production. Put us to the test for your next project and call one of our account managers on 01480 226699 or use our customer enquiry form, we would love to hear from you.

start your production journey today

If you are looking to find a complete service include dedicated engineering to design and implement your solution, get in touch with us. You’ll be allocated your own dedicated account manager who is always on hand to advise and take care of everything for you. Call Photofab on 01480 226699 or contact us now to see how Photofab can add an extra dimension to your manufacturing project. Keep up to date by following us on LinkedIn and Twitter.

TAKE A LOOK AT OTHER

PRODUCTS FROM PHOTOFAB

To find out how we can help you

Get in touch today