The Growing Demand for Lightweight Metal Components in Modern Military Systems

In the current age of rapid technological advancement and evolving political and military threats, the defence and aerospace sectors face an unrelenting pressure to achieve more with less. One of the most critical engineering challenges driving innovation in the 21st century is the strategic pursuit of weight reduction, or ‘lightweighting’.

The demand for high-precision, lightweight metal components is no longer a nice-to-have but the central foundation in the development of next-generation military systems. In this article, we’ll explore the compelling drivers behind this trend and examine why advanced manufacturing processes, particularly photochemical etching, are becoming indispensable to meeting these ambitious goals.

Why is Lightweighting Important in Defence?

A combination of operational, economic and tactical factors drives the push for lighter military assets. Reducing mass delivers a cascade of performance benefits across all domains of air, land, sea and space.

- Enhanced Fuel Efficiency and Extended Range – Every kilogram saved in an aircraft, naval vessel, or ground vehicle translates directly into reduced fuel consumption. This enables longer missions, greater operational range and significant reductions in logistical burdens and lifecycle costs.

- Increased Payload and Sensor Capacity – The weight saved through component lightweighting can be reallocated to mission-critical payloads. This could mean additional munitions, more advanced sensor suites, electronic warfare systems, or vital supplies, directly enhancing platform capability.

- Improved Agility, Speed and Mobility – For fighter jets and unmanned aerial vehicles (UAVs), reduced mass improves thrust-to-weight ratios, enabling superior acceleration, climb rates and manoeuvrability. For the foot soldier, lighter personal equipment and vehicle components enable greater mobility and reduce fatigue.

- Advancements in Soldier Systems – Modern infantry equipment, from ballistic plates and helmet systems to communications gear and exoskeletons, relies on lightweight, high-strength materials to improve protection without compromising a soldier’s ability to move and fight effectively.

The Manufacturing Challenge – Precision at Minimal Weight

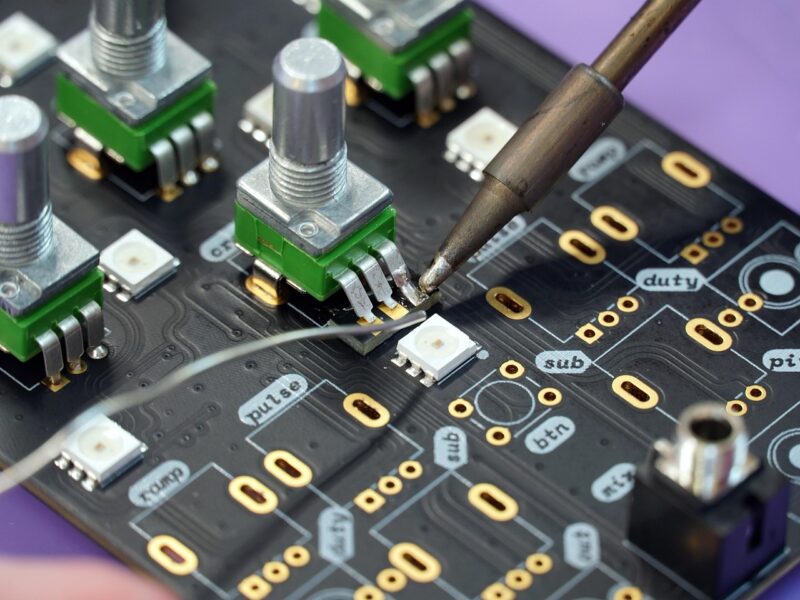

Achieving these weight reductions cannot come at the expense of reliability or performance. Components must often be fabricated from advanced, hard-to-machine alloys like titanium and high-strength, corrosion-resistant stainless steels. They often feature complex geometries, fine apertures and burr-free edges, which are essential for optimal performance in sensitive applications such as radar arrays, optical systems and fuel cells.

This is where traditional manufacturing methods, such as stamping and laser cutting, can reach their limits. Stamping induces mechanical stress and work-hardening, which can compromise the integrity of thin, high-strength materials. Laser cutting, while precise, generates heat-affected zones (HAZ) that can alter material properties and create micro-fractures.

Photochemical Etching – The Precision Solution for Defence Applications

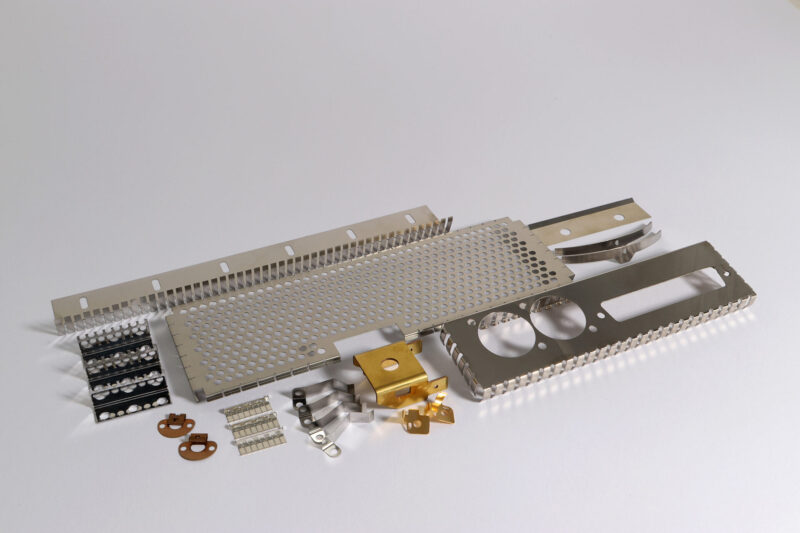

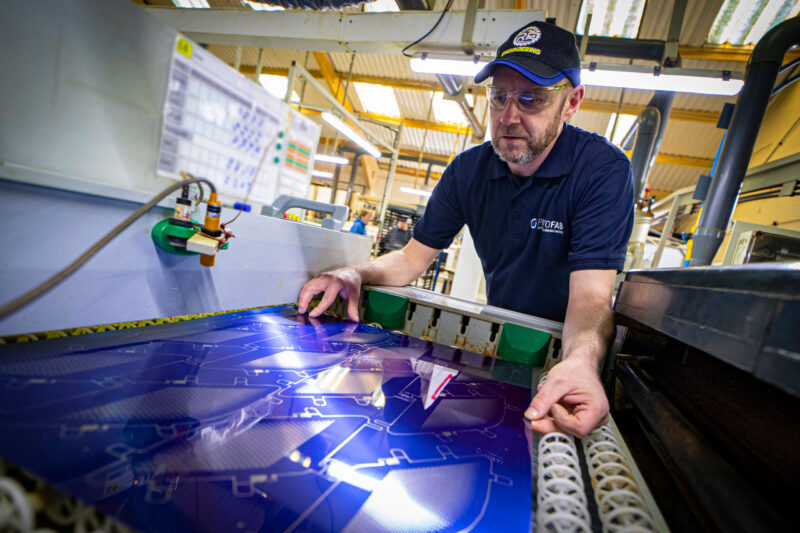

Photochemical etching is a subtractive manufacturing process that addresses these challenges head-on, making it ideally suited to producing the lightweight, complex components required by modern military systems. Photofab specialises in this advanced technique, which offers distinct advantages for the aerospace and defence sectors.

How Photochemical Etching Works for Defence Components:

- A photoresist is applied to the metal sheet.

- A CAD-designed phototool is used to expose and develop the desired component pattern.

- A chemical etchant selectively removes metal, leaving a precision part with no contact stresses or thermal distortion.

Key Benefits of Photochemical Etching for Military & Aerospace:

- Stress and Burr-Free Production – As a non-contact, non-thermal process, photochemical etching introduces no mechanical stresses or thermal distortion. Components are produced with absolutely no burrs, crucial for assemblies where even a micron-scale imperfection can cause failure.

- Exceptional Precision and Complexity – The process can reliably produce intricate geometries, fine meshes, and sharp edges that are difficult or impossible to achieve with other methods, while maintaining tight tolerances.

- Material Integrity Preservation – The absence of heat and force means the inherent properties of specialised alloys, such as the strength-to-weight ratio of titanium or the corrosion resistance of stainless steel, are completely preserved.

- Rapid Prototyping to High-Volume Production – Design changes are implemented at the phototool stage, allowing for fast, cost-effective iterations. The same tooling can then be used for consistent, scalable production runs.

Comparing Manufacturing Methods for Lightweight Components

| Feature | Photochemical Etching | Traditional Stamping |

| Stress/Burrs | None. The cold process ensures no work hardening or burrs. | Present. Mechanical force creates stress and burrs requiring secondary removal. |

| Heat-Affected Zone (HAZ) | None. Ideal for sensitive thermal properties. | Possible in laser/plasma variants. Can alter material microstructure. |

| Design Flexibility | Extreme. No cost penalty for complexity; ideal for prototypes. | Limited. High tooling costs for complex designs. Best for high-volume, simple shapes. |

| Lead Time for Tools | Very Short (hours/days). Digital phototools. | Long (weeks/months). Hard tooling required. |

| Material Suitability | Excellent with all ductile metals, including hard-to-machine alloys. | It can be challenging with very hard or brittle alloys without causing damage. |

Critical Materials for Lightweight Defence Components

Photochemical etching is versatile, working with a range of metals essential for defence applications:

- Titanium Alloys – The benchmark for high strength-to-weight ratio, exceptional corrosion resistance and biocompatibility. Ideal for aerospace structures, marine components and medical devices in field hospitals.

- Stainless Steels – Offer an excellent balance of strength, corrosion resistance, and cost-effectiveness for a wide range of components.

- Aluminium Alloys – Provide very low density and good conductivity, used in enclosures, heat sinks, and lightweight frames.

- Copper, Brass, and Nickel Alloys – Chosen for superior electrical and thermal conductivity in connectors, EMI/RFI shielding and heat exchanger components.

Applications in Modern Military Systems

The combination of lightweight materials and photochemical etching’s precision enables breakthroughs across defence platforms:

- Aerospace & Avionics – Mesh filters for fuel and hydraulic systems, lightweight antenna components for communication arrays, precision shims and seals in jet engines and EMI shielding gaskets.

- Electro-Optical & Sensor Systems – Apertures, encoder discs, flexures and shielding for targeting pods, night vision systems, and satellite sensors, where precision is paramount.

- Unmanned Systems (UAVs/UUVs) – Extremely lightweight structural frames, heat sinks for onboard electronics and intricate parts for miniaturised guidance systems in drones and underwater vehicles.

- Soldier Modernisation – Components for lightweight communication devices, battery contacts and specialised parts for advanced optical sights and weapon systems.

Partnering for Advanced Defence Manufacturing

The strategic drive for lightweighting in defence is an important development. Meeting this demand requires a manufacturing partner capable of transforming them into flawless, high-performance components without compromising their intrinsic properties.

As a trusted, UK-based specialist in photochemical etching, we provide the certified expertise and cutting-edge capability needed to manufacture the critical, lightweight components that modern military systems depend on. Our process ensures the precision, reliability and integrity required for the most demanding aerospace and defence applications.

Ready to explore how photochemical etching can advance your lightweight component strategy? Talk to one of our specialists today.