Prototyping is a critical part in every manufacturing process, a time sensitive and necessary step to ensure the success of high-volume production. Understanding this has enabled us to develop full-service prototyping, which offers a cost-effective and flexible package aiming to exceed customer’s expectations on quality and delivery. With over 55 years of experience, we can be trusted to provide a full service – from prototyping your parts to full-scale, high-volume production.

We offer our services in every possible volume – we can prototype single pieces and scale all the way up to a high-volume production. We offer this flexibility in a range of our industry leading processes.

For more information on how we can reduce your costs & improve lead time contact our dedicated account managers on 01480 226699 or email enquiries@photofab.co.uk.

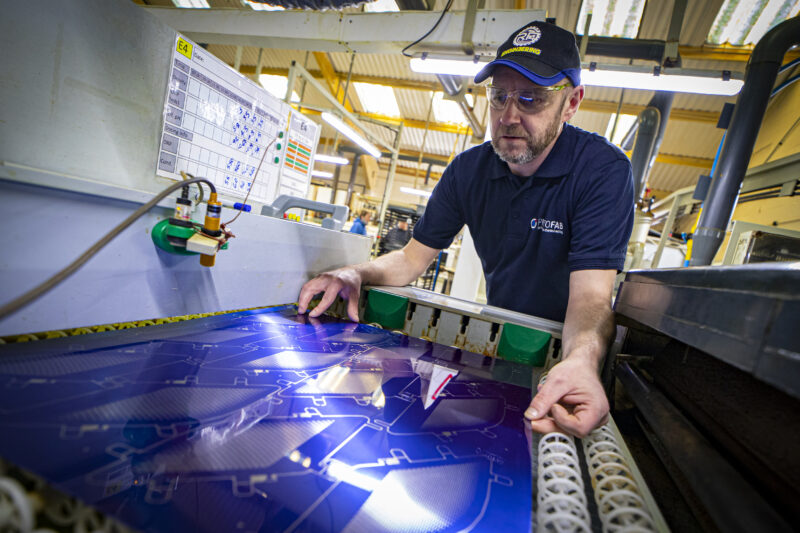

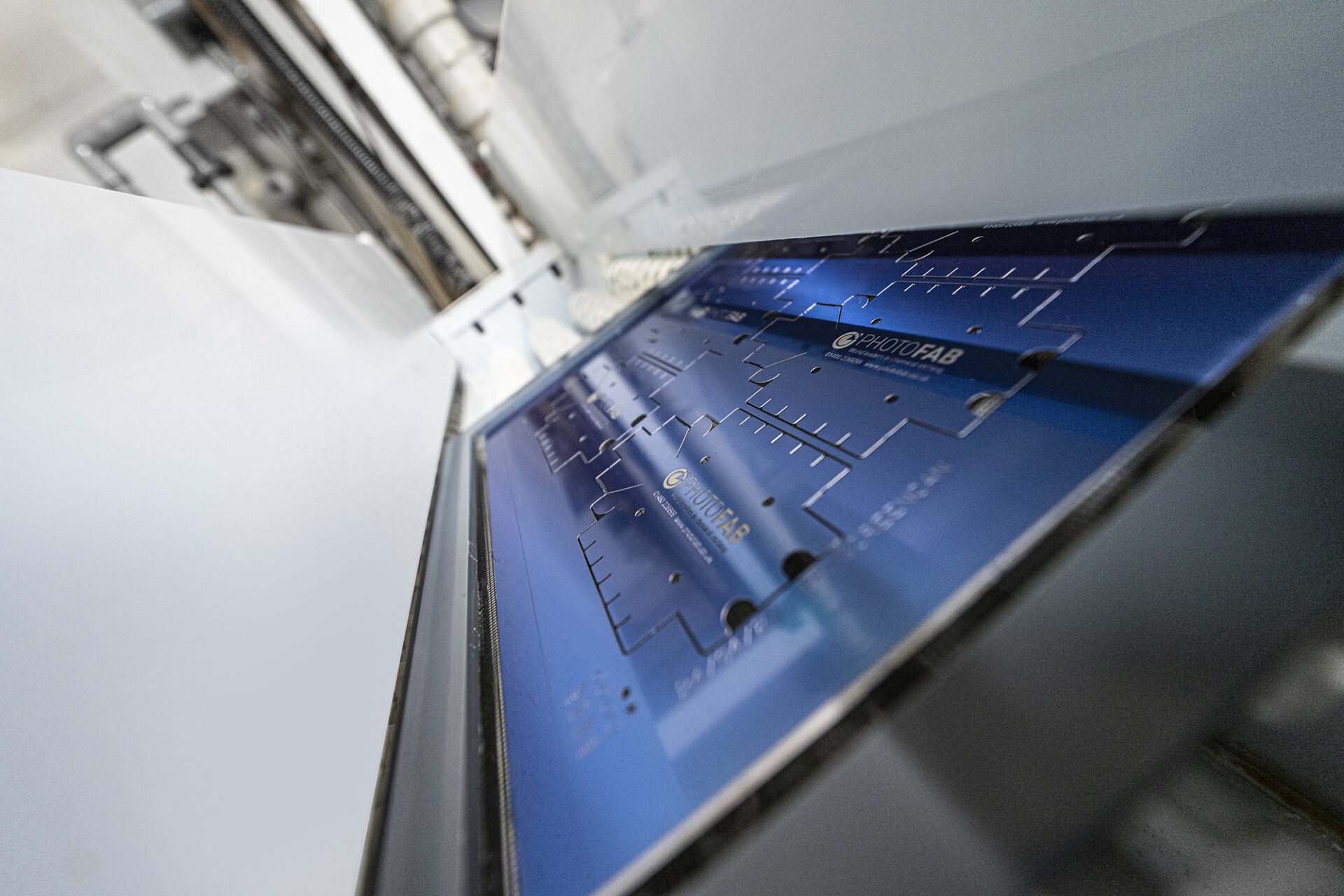

THE DIGITAL Advantage

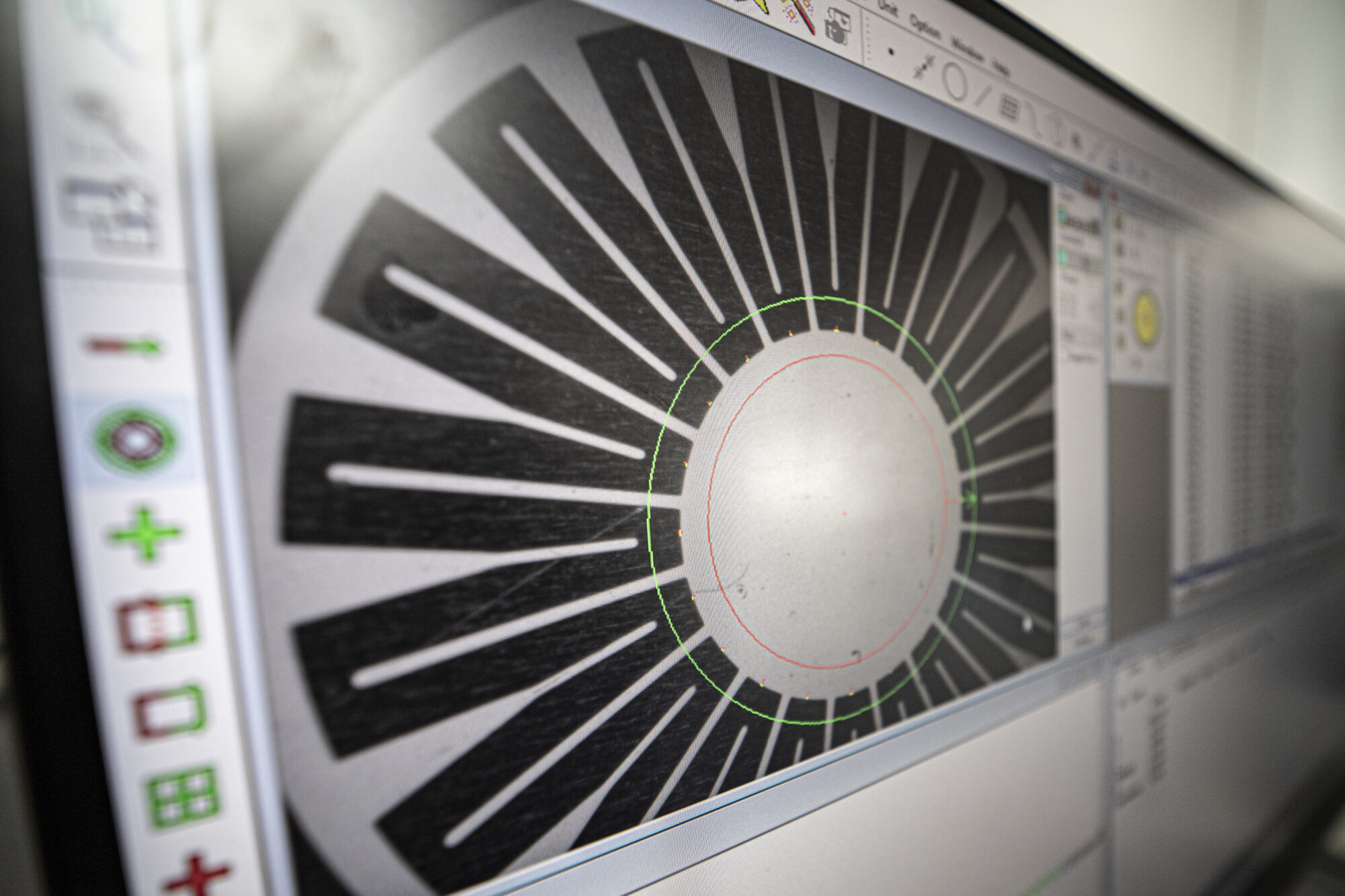

For prototyping, our state-of-the-art digital workflow allows us to quickly adjust and reprint tool designs, allowing tweaking and testing until the final tool is perfect for the application. Our computer systems can read almost all electronic drawing files at the quotation stage. When we start manufacturing, we encourage the use of CAD files: .dwg, .dxg .STEP or .IGES, but we can also accept image files such as .eps, .pdf, .cdr or .ai. You can upload your files straight to us at the quotation stage, so please don’t hesitate to contact us.

If your file format is not shown, or if you want to discuss our digital toolset, please get in touch so we can better understand your prototyping needs with one of our experts – you will be assigned a dedicated account manager who will handle all your queries and the processing of your order.

A TRACK Record of Success

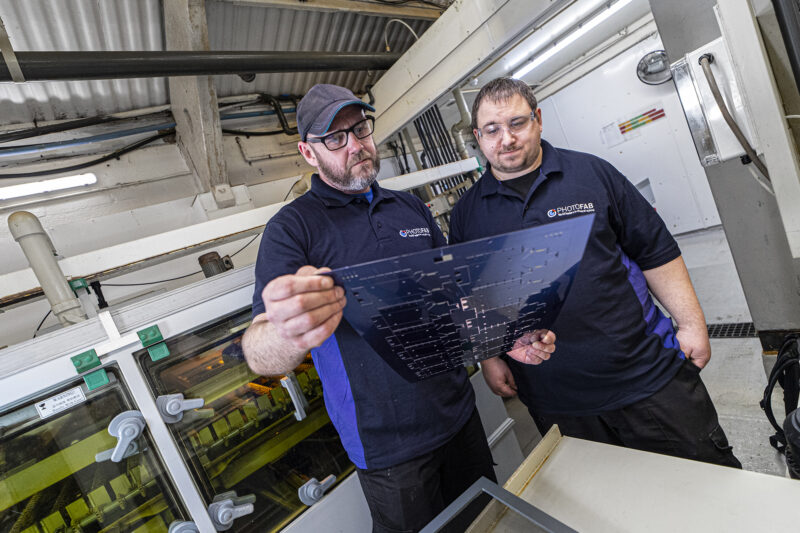

We have delivered at every volume. Our dedicated engineers can help you design prototypes that are suitable for production to meet your specification. We also have experience in delivering low- medium volume orders, in the form of short run production, and have delivered outstanding results in a timely manner in a proven track record.

We even offer a supplier in the Far East for very high-volume orders, which is all handled, and quality assured by us. We take complete control of the supply chain, and guarantee quality as high as what we produce ourselves.

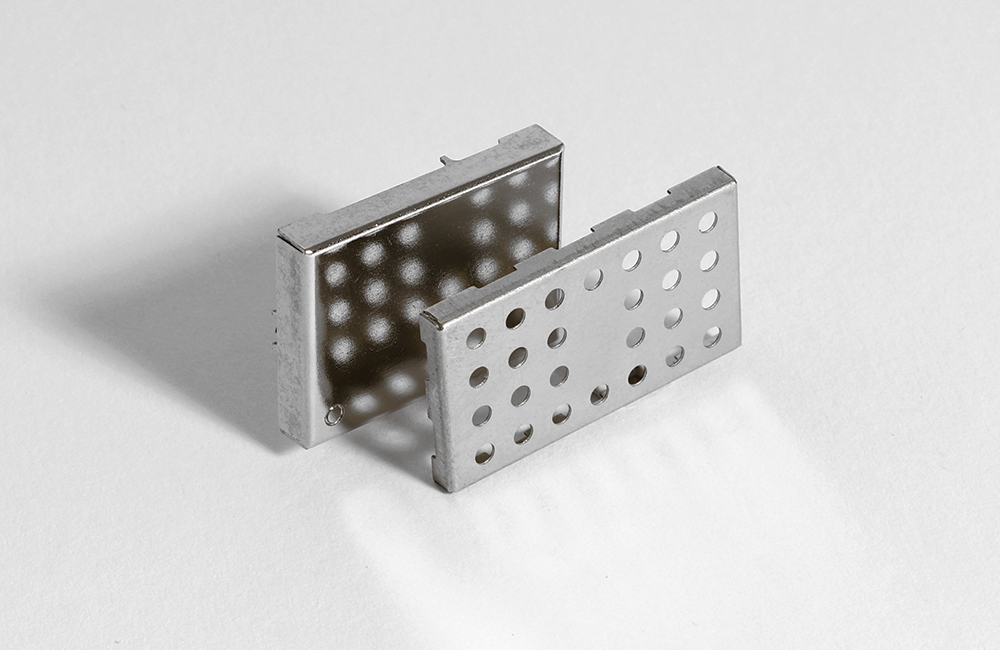

Prototyping Case Study

A client asked us to produce two prototype components at extremely short notice. The order was placed late on a Friday afternoon. Thanks to our expertise, hard work and digital toolset, we were able to deliver the final prototypes by the following Monday morning, half-etched for simple hand forming. Just a small example of how we can deliver prototyping on short notice.

Medium Volume Case Study

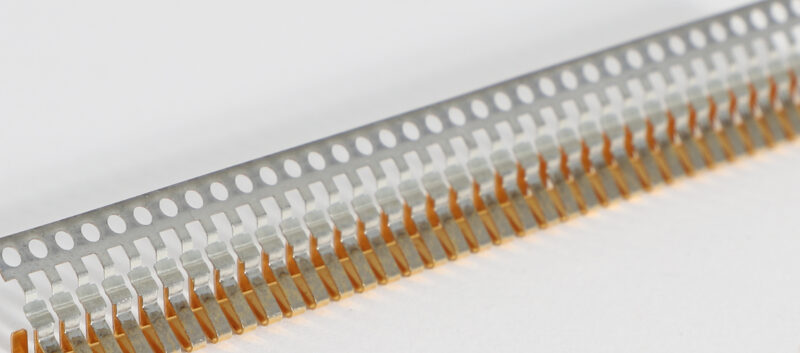

We were asked to produce 10,000 Encoder discs for a company making incremental encoders; manufactured from 0.6 mm thick stainless steel, packed in units of 10. A short run can be the number of components that can be made from one sheet (nominally 300x500mm) up to several hundred sheets. The greater the number of sheets that can be processed for one job, the lower the price will be. Our expertise allowed us to maximise output per sheet, giving the customer better return on investment.

High Volume Case Study

An ongoing order from a client that required 20,000 formed screening cans required every week, plated with brass, fitted into mobile communication equipment. We offered our two modern manufacturing options available for high volume production, our own facilities based in the UK and our close partner in the Far East – advising the client on the pros and cons of each service and allowing them to decide what was best for their business.

A WORLD of Options

Our full service means that our customers have an incredible variety of services available. From prototyping with our design team with a huge range of materials, through to full-scale, high-volume production. Our range of metals gives a huge amount of flexibility and allows you to pick the best material depending on your application.

We understand that the three critical parts of a successful prototyping operation are Quality, Cost and Speed. Our success in prototyping arises from a deep understanding of the importance of these key ingredients. By listening and understanding the needs of our customers we can draw on our extensive knowledge and expertise to better advise and plan the best manufacturing processes. This refined process produces quality precision products that are cost-effective and delivered in the shortest time possible.

Whatever your volume requirements, whether it’s a single prototype or a high-volume order, let us manage the service for you. Call today on 01480 226699 or contact us using the form below.

DEDICATED engineering

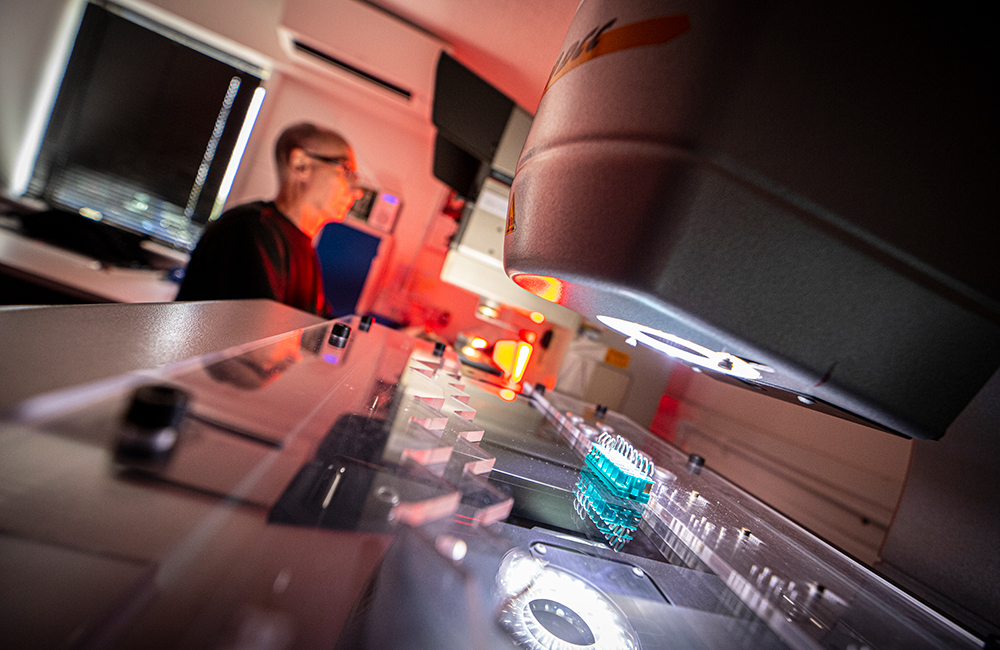

We understand the importance of skilled engineering when designing components and putting them into production. Therefore, we have heavily invested in a dedicated secondary engineering unit, the aim of this is to offer an even greater service and flexibility to our customers.

Originally set up to provide an in-house solution to support the etching division, it has proven so popular with our customers that we are now offering toolroom, forming and finishing as stand-alone services. This means our customers now have access to a new level of flexibility – enjoying the convenience of full-service manufacture or pick and choose services to suit them. It truly is a complete service we offer.

We continue to offer cutting-edge services and outstanding lead times, and we can do so because of continuous investment in our people and our processes, leading to class-leading output and lead times – including our rapid 24 hour turnaround service.

The benefits of

working with us

We are world leaders in the development of photochemical technology to produce intricately shaped components. We have produced over 80,000 different components over the years and are highly regarded for our chemical etching process. Our engineers offer many services, and will offer advice to improve the product and reduce the costs.

24-hour quotation service

Dedicated account managers

Rapid manufacturing service

Cost saving stock of uni-tooling

Etched fold lines for tool-free forming

Full manufacturing service and supply chain management

Access to manufacturing and technical advice and expertise

Quality accredited to ISO 9001, ISO 14001, ISO 45001 and SC21 Bronze

The key difference

One of the key reasons we achieve high levels of customer retention and longevity is the team of dedicated account managers. This ‘single point of contact’ throughout the whole process, ensures a personal service, and pride in the quality and reliability of the entire service.

Customers rely on their dedicated contacts’ understanding and in-depth knowledge of their specific requirements and know the highest standards will always be met using the most efficient and cost-effective methods.

This consistent service is the foundation of our customer loyalty and is maintained throughout every department and every stage of production. Put us to the test for your next project and call one of our account managers on 01480 226699 or use our customer enquiry form.

Value added partnerships

We also have long working relationships with specialist partners for additional finishing services. These services can range from laser-cutting, plating, anodising and heat treatments which can add decorative finishes, prevent corrosion, and further improve durability.

All additional processes are managed closely and delivered with full transparency and traceability.

start your production journey today

If you are looking to find a complete service include dedicated engineering to design and implement your solution, get in touch with us. You’ll be given an account manager who is always on hand to advise and take care of everything for you. Call us on 01480 226699 or contact us now to see how we can add an extra dimension to your manufacturing project. Keep up to date by following us on LinkedIn.

TAKE A LOOK AT OTHER

SERVICES we offer

To find out how we can help you

Get in touch today